Why the Right to Repair Your Phone, Tractor, and EV Is Suddenly a Global Tech Story

A decade ago, asking “Can I repair my phone?” was a niche concern. Today, repairability is a headline metric in product reviews, a battleground for regulators, and a deciding factor for buyers choosing their next smartphone, laptop, tractor, or EV. Lawmakers are passing right‑to‑repair rules, manufacturers are unveiling self‑service repair portals, and teardown videos on YouTube and TikTok are nudging industrial design away from glue and proprietary screws toward modular, maintainable hardware.

This long-form guide unpacks how right to repair went mainstream: the legal milestones, the technology and software locks at the heart of the debate, the stakes for farmers and EV owners, and what all of this means for the lifespan, cost, and environmental impact of the devices you rely on every day.

Mission Overview: How Right to Repair Went Mainstream

The core idea behind right to repair is simple: if you own a device, you should be able to fix it—or choose who fixes it—without being blocked by artificial technical, contractual, or legal barriers. What was once driven largely by grassroots groups like iFixit, Repair.org, and local repair shops is now embedded in national legislation and corporate roadmaps.

Several converging forces pushed right to repair into the mainstream:

- Legislation: New rules in the EU, UK, and multiple U.S. states mandate access to spare parts, repair manuals, and diagnostic tools for years after purchase.

- Corporate pivots: Major brands have launched self‑repair programs, opened parts stores, and extended software support timelines.

- High‑profile teardowns: iFixit and similar channels turned repairability scores and teardown footage into viral, shareable content.

- New frontiers: Farmers and EV owners pushed the debate beyond consumer gadgets into tractors, industrial equipment, and electric drivetrains.

- Climate and cost pressures: Governments and consumers now see repairability as a lever to cut e‑waste and save money.

“We’ve gone from asking whether right to repair is legitimate policy to debating how far it should go. That’s a profound shift in just a few years.”

— Kyle Wiens, CEO of iFixit, in interviews on evolving repair legislation

Legislative Milestones: From Niche Bills to Global Policy

Legislatures around the world now treat repairability as a core consumer‑rights and sustainability issue. While details vary by jurisdiction, recent laws converge on three main obligations for manufacturers:

- Provide spare parts for a minimum number of years.

- Publish repair documentation and service manuals.

- Offer or enable diagnostic software and tools on fair terms.

Europe’s Eco‑Design and Repair Rules

The European Union has led on tying repairability to climate and circular‑economy goals. Regulations now require certain categories of products—washing machines, displays, refrigerators, and increasingly electronics—to meet eco‑design and repairability criteria, including:

- Mandatory availability of key spare parts (e.g., screens, batteries, hinges) for up to 7–10 years.

- Reasonable delivery times for those parts (often within 15 working days).

- Standardized metrics for repairability and energy performance on product labels.

Proposals under the broader European Green Deal and the Right to Repair initiative aim to expand coverage to smartphones, tablets, and laptops, with explicit requirements for software support duration and repair‑friendly design.

United States: State‑Level Momentum

In the U.S., right‑to‑repair policy has advanced primarily via state laws, with pressure mounting on federal regulators:

- State statutes: By 2024, states such as New York, Minnesota, and California had passed consumer‑electronics right‑to‑repair laws, with others considering similar bills.

- Agriculture settlements: Legal settlements involving major tractor manufacturers have opened limited diagnostic access for farmers, though critics argue they stop short of full repair rights.

- Federal guidance: The U.S. Federal Trade Commission (FTC) has signaled support for right to repair, releasing reports critical of anti‑repair practices.

“There is scant evidence to support manufacturers’ justifications for repair restrictions… and significant evidence that these restrictions harm consumers and small businesses.”

— U.S. Federal Trade Commission report on repair restrictions

Key Loopholes and Ongoing Debates

Reporting from outlets like Wired and Ars Technica highlights recurring grey areas:

- What counts as a “fair price” for spare parts?

- Can manufacturers still tie parts to a device’s serial number via firmware locks or parts pairing?

- How long must firmware updates support interoperability with third‑party components?

These details will determine whether laws genuinely empower independent repair or simply formalize limited, tightly controlled ecosystems.

Big‑Tech Policy Changes: Self‑Repair Programs and Longer Support

Under regulatory and public pressure, major device makers have shifted from outright opposition to controlled accommodation of repair. Policy moves vary by company but follow several patterns.

Self‑Service Repair and Official Parts Stores

Prominent phone and PC brands now offer:

- Self‑repair portals where customers can rent or buy specialized tools.

- Official parts catalogs for screens, batteries, cameras, and ports.

- Publicly accessible service manuals and disassembly guides.

Publications like The Verge and Engadget routinely test these programs, often finding:

- Parts pricing can be close to the cost of professional third‑party repair.

- Toolkits are comprehensive but sometimes overkill for a one‑off fix.

- Software activation steps (e.g., serial‑number pairing) can be intimidating.

Extended Software Support Windows

Right to repair isn’t just about hardware. Long‑term software support is crucial for both functionality and security. Many manufacturers now advertise:

- Multi‑year OS upgrades (often 4–7 years on premium models).

- Security patches beyond the OS‑upgrade window.

- Public support lifecycle roadmaps that buyers can compare before purchasing.

For technically inclined users, this opens the door to maintaining a device far beyond the traditional 2–3‑year replacement cycle—especially when combined with battery and storage upgrades.

How Practical Are These Programs?

Independent repair shops and reviewers frequently benchmark manufacturer self‑repair programs against local repair businesses. Typical findings include:

- Manufacturer programs score well on documentation quality but poorly on price.

- Independent shops offer speed and convenience—no need to ship devices or manage tool rentals.

- Authorized partners sometimes face contractual limits on which repairs they can perform.

The result is a hybrid ecosystem where self‑repair, authorized service, and fully independent repair coexist—often uneasily.

Beyond Gadgets: Farm Equipment, EVs, and Proprietary Software

Perhaps the most dramatic right‑to‑repair clashes have occurred not over phones but tractors and electric vehicles. In these domains, software is deeply intertwined with physical hardware, and downtime has direct economic and safety implications.

Tractors and Agricultural Equipment

Modern tractors are rolling computers, packed with electronic control units (ECUs), GPS‑guided steering, and telematics. Farmers increasingly report:

- Being locked out of diagnostic codes required to troubleshoot breakdowns.

- Needing authorized dealers for software‑enabled repairs after replacing parts.

- Facing harvest‑critical delays when dealer technicians are unavailable.

Investigations by outlets like Ars Technica’s tech‑policy section describe farmers turning to:

- Unofficial firmware unlock tools sourced online.

- Third‑party diagnostic software mirroring dealer capabilities.

- Advocacy groups lobbying for agricultural right‑to‑repair laws.

“When my tractor is down in the middle of harvest, I can’t afford to wait days for a dealer to show up just to run a diagnostic I could do myself if they’d let me.”

— Midwestern U.S. farmer quoted in multiple right‑to‑repair hearings

Electric Vehicles and High‑Voltage Systems

EVs add new layers of complexity to the repair debate:

- Battery health and replacement: High‑capacity packs are expensive and tightly integrated; software may restrict third‑party replacements or used modules.

- Drivetrain and power electronics: Specialized components require both safety training and diagnostic access.

- Over‑the‑air (OTA) updates: Firmware pushes can silently change compatibility behavior, sometimes disabling third‑party components.

Some independent EV specialists have emerged, but many operate in a grey zone depending on how aggressively manufacturers enforce software locks on batteries and modules.

Software Locks, Secure Enclaves, and Parts Pairing

Across tractors, EVs, and consumer devices, three technical mechanisms recur:

- Parts pairing: Components (screens, batteries, cameras) are cryptographically tied to a device’s main board. Replacements must be “authorized” by running proprietary calibration tools.

- Secure enclaves: Security‑critical functions run in isolated hardware areas that may refuse to work with non‑whitelisted components.

- Remote attestation: Cloud services or OTA updates can check component authenticity, potentially disabling unsupported third‑party parts.

On Hacker News and similar forums, engineers dissect these mechanisms, debating where legitimate security ends and anti‑competitive lock‑in begins.

Teardowns, Repair Scores, and the Social‑Media Effect

Right to repair’s cultural breakthrough came in large part from highly visual content: teardown videos, livestreamed repairs, and side‑by‑side comparisons of repairability scores. These formats turned otherwise abstract policy arguments into something tangible and shareable.

iFixit and the Rise of Repairability Scores

iFixit pioneered public teardown guides and numeric repair scores, typically on a 0–10 scale. A high score reflects:

- Use of standard screws instead of proprietary fasteners.

- Modular design for batteries, storage, and key components.

- Minimal adhesive or adhesive that is easy to remove safely.

- Availability of parts and manuals to the general public.

These scores are now:

- Cited in reviews from TechRadar and Engadget.

- Discussed in YouTube reviews that compare both performance and repairability.

- Used by eco‑labels and public procurement frameworks evaluating sustainable IT.

Buyer’s Guides Now Ask “How Long Will This Last?”

As enforcement of right‑to‑repair rules increases, the central consumer question has shifted:

- From: “Can I repair this device at all?”

- To: “For how many years is this device realistically repairable and supported?”

Modern buyer’s guides routinely include:

- Estimated years of OS/security updates.

- Battery replacement difficulty and cost.

- Whether storage or RAM is soldered or user‑upgradeable.

This approach makes repairability a visible dimension of product value, not an afterthought.

Scientific and Environmental Significance

Beyond consumer convenience, right to repair intersects with climate policy, materials science, and lifecycle assessment. Analysts at publications like Wired’s e‑waste coverage and The Next Web quantify how repairing devices can reduce global resource consumption.

Lifecycle Emissions and Resource Use

A substantial share of a device’s total carbon footprint is embedded in manufacturing, not in day‑to‑day use. For smartphones and laptops, this often means:

- Extending a device’s life from 3 to 6 years can roughly halve its annualized carbon impact.

- Replacing a battery or SSD has a fraction of the material footprint of purchasing new hardware.

- Keeping devices alive longer reduces pressure on mining for critical minerals like cobalt and rare earth elements.

Economic and Social Dimensions

Repair access also affects economic resilience and equity:

- Affordable repair options are critical in lower‑income communities and emerging markets.

- Local repair businesses keep spending within communities and create skilled jobs.

- Access to repair helps bridge the digital divide by extending the usable lifespan of donated or refurbished devices.

“Every time we fix a device instead of tossing it, we save the resources and emissions that would have gone into making a new one. Scaled up across millions of devices, repair becomes a powerful climate tool.”

— Repair and circular‑economy researchers writing in environmental policy journals

Security, Safety, and the Limits of Openness

Manufacturers often justify tight repair control on safety and cybersecurity grounds. The reality is nuanced: some restrictions are genuinely safety‑critical, while others mainly protect business models.

Legitimate Safety Concerns

There are areas where strong safeguards are necessary:

- High‑voltage systems: EV batteries and power electronics require strict handling protocols.

- Medical devices: Incorrect repairs can pose direct health risks.

- Critical infrastructure: Industrial controls and safety‑relevant automation must minimize tampering risks.

Many right‑to‑repair advocates support training and certification frameworks for independent technicians in these domains rather than blanket bans.

Security Through Obscurity vs. Open Repair

Cybersecurity experts frequently argue that:

- Hiding schematics and firmware does not guarantee security; determined attackers can still reverse‑engineer systems.

- Independent scrutiny can reveal vulnerabilities faster than closed ecosystems.

- Restrictive design can break legitimate repairs, leading to more unsafe DIY hacks.

Well‑designed systems can combine cryptographic authentication, secure enclaves, and audited APIs with open access to parts and documentation, balancing security with user autonomy.

Key Milestones and Emerging Trends

The right‑to‑repair story is now a sequence of clear milestones and accelerating trends that span policy, design, and consumer behavior.

Notable Milestones (2019–2025)

- Multiple EU eco‑design regulations include mandatory spare‑parts availability and repair requirements.

- Several U.S. states pass electronics right‑to‑repair laws, with more in the pipeline.

- Large OEMs launch official self‑service repair programs across multiple regions.

- Major tractor brands enter settlements granting farmers some diagnostic access.

- Tech reviewers and buying guides standardize on repairability sections in product coverage.

Emerging Design Patterns

Industrial design is responding to both regulation and consumer demand:

- Modular laptops with easily replaceable ports, storage, and even mainboards.

- Glue‑free batteries that can be removed with pull tabs or simple tools.

- Standardized screws across product lines to simplify repair tooling.

- Cloud‑linked diagnostics that can be securely shared with independent repairers.

These changes don’t just benefit repair advocates—they also simplify in‑warranty service and reduce manufacturers’ own support costs.

Practical Technology and Tools for Consumers

For individuals, the mainstreaming of right to repair translates into concrete options when something breaks. A structured approach helps you decide when to repair and when to replace.

Step‑by‑Step: Deciding What to Do When a Device Fails

- Assess warranty status: Check if your device is still under manufacturer or retailer warranty or covered by consumer‑protection laws.

- Search for official documentation: Visit the manufacturer’s support site for manuals or repair guides.

- Consult independent resources: Look up teardown and repair guides on sites like iFixit and community forums.

- Compare quotes: Get price estimates from:

- The manufacturer’s repair program.

- A local independent repair shop.

- DIY repair using purchased parts and tools.

- Evaluate environmental and budget impact: Favor repair if the cost is significantly below replacement and the device remains well‑supported.

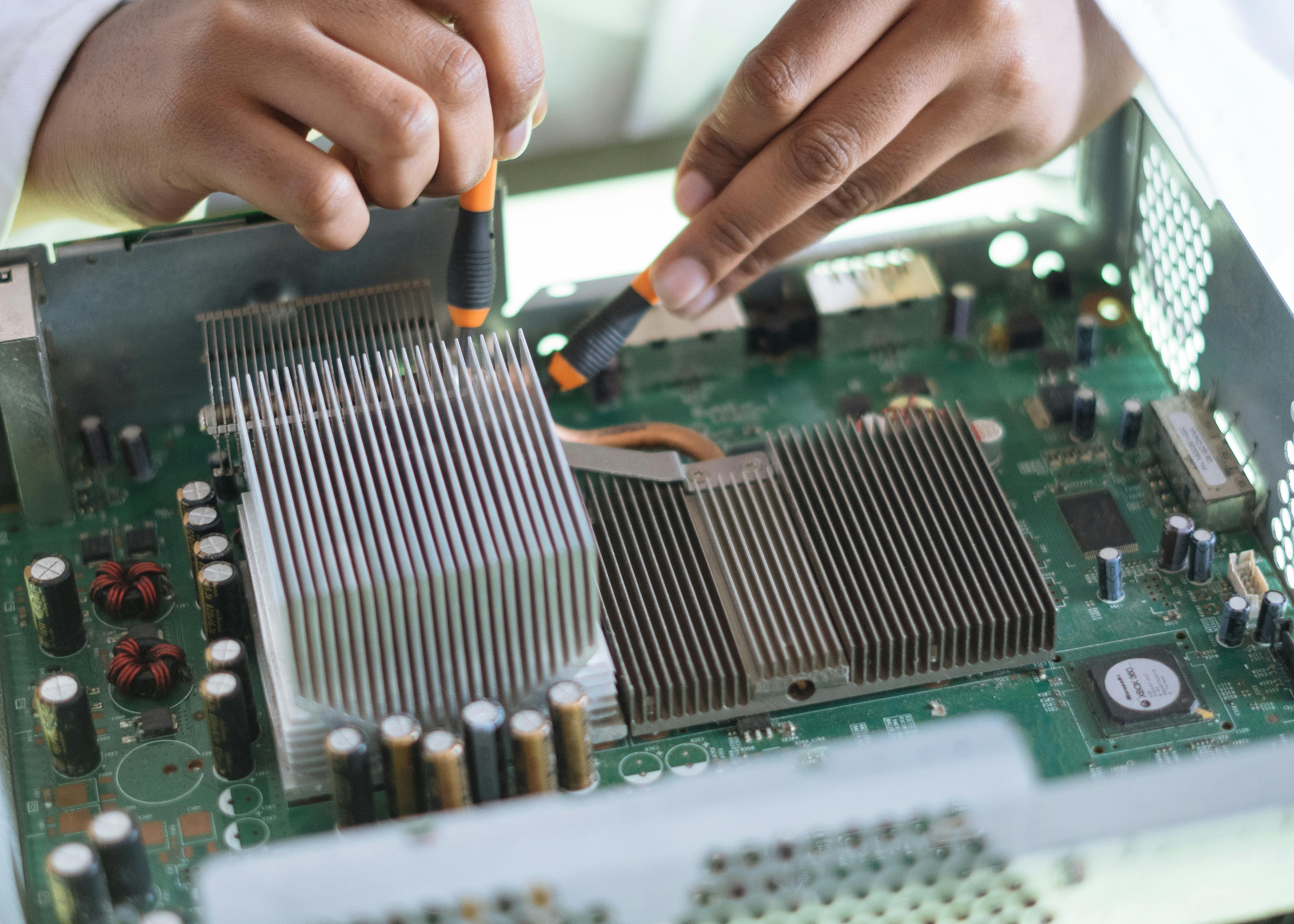

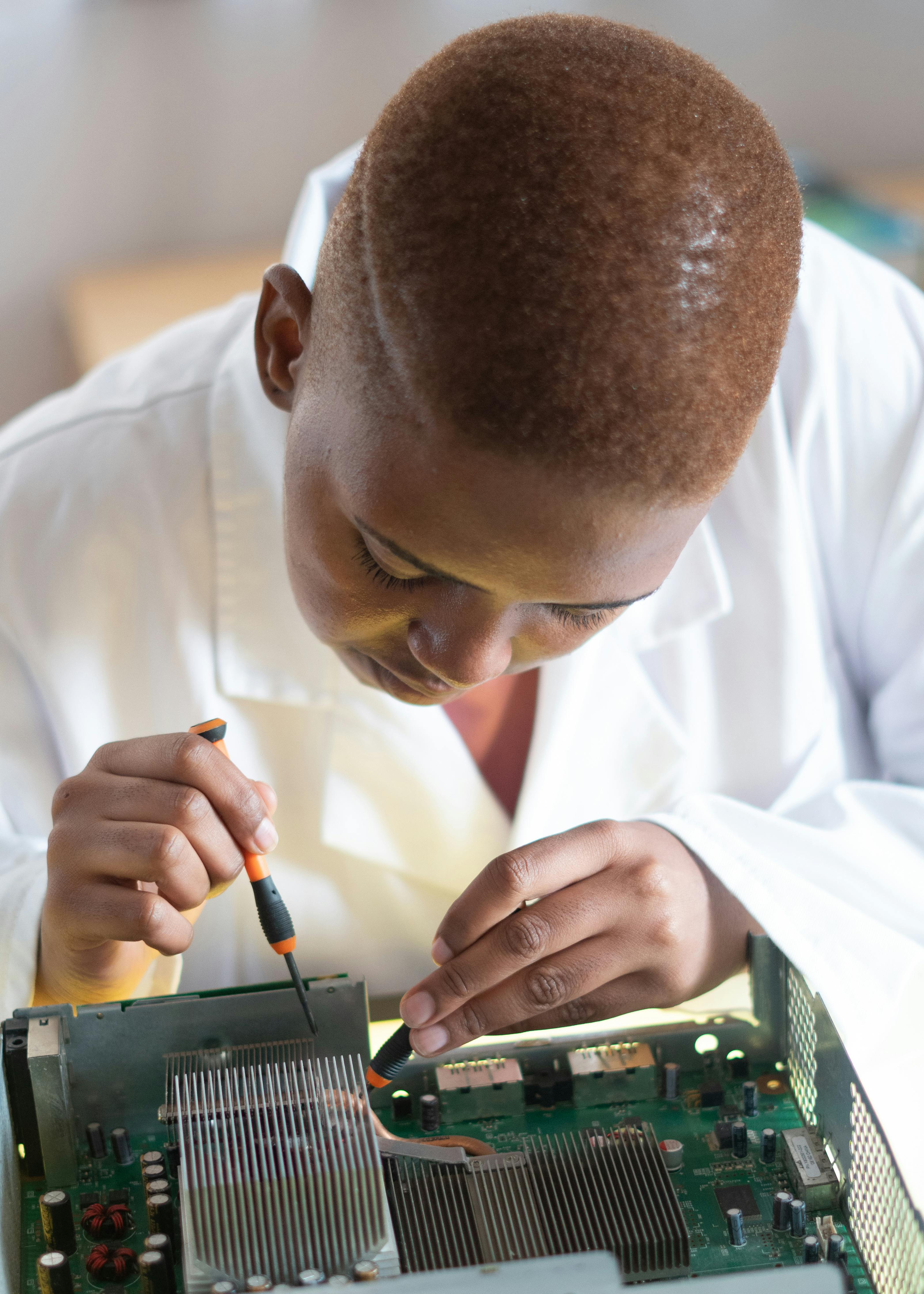

Tools and Kits for Safe Home Repair

If you are comfortable with DIY, high‑quality tools are critical for reducing risk. Popular options in the U.S. include:

- A precision screwdriver set such as the iFixit Mako Driver Kit , which offers a broad range of bits for phones, laptops, and game consoles.

- An electronics repair toolkit like the iFixit Essential Electronics Toolkit , including spudgers, tweezers, and opening picks.

- For more advanced work, a magnetic work mat and parts organizer such as the iFixit Magnetic Project Mat can help track screws and components.

Always follow ESD (electrostatic discharge) precautions and consult step‑by‑step guides before opening any device.

Challenges and Unresolved Questions

Even as right to repair gains momentum, several structural challenges remain that will shape how effective these reforms become.

Global Fragmentation of Rules

Manufacturers operate across jurisdictions with differing, sometimes conflicting, requirements:

- Regional product variants may receive different levels of repair support.

- Smaller manufacturers struggle to keep up with documentation and parts‑stock obligations.

- Cross‑border e‑commerce complicates the enforcement of local rules on global platforms.

Economic Incentives and Design Trade‑Offs

Engineering teams must balance:

- Thinness and ruggedness versus modularity.

- Waterproofing versus easy disassembly.

- Short‑term margins from frequent hardware refreshes versus long‑term brand trust from durable, repairable products.

Some companies view repairability as a competitive advantage; others see it primarily as compliance overhead.

Data Privacy in Repair Workflows

As more entities gain diagnostic access, new privacy concerns arise:

- How is user data protected when devices are sent to third‑party repair centers?

- Can diagnostic logs reveal location or usage patterns beyond what is necessary for repair?

- Who is accountable for data breaches in the repair chain?

Emerging best practices include mandatory factory resets before repair, encrypted storage by default, and privacy‑focused repair policies.

Conclusion: From Ownership to Stewardship

Right to repair’s mainstream moment is reshaping what it means to own technology. Instead of treating phones, laptops, tractors, and EVs as sealed, disposable appliances, consumers and policymakers increasingly see them as long‑lived assets that should be maintainable, upgradeable, and interoperable.

Over the next few years, key battlegrounds will include:

- The scope and enforcement of parts‑pairing restrictions.

- Minimum standards for software support duration.

- Repairability requirements for new product categories, from smart home devices to industrial robotics.

For buyers, the practical takeaway is clear: repairability now belongs alongside price, performance, and brand reputation in any purchasing decision. Asking how long a device will be supported—and how easily it can be fixed when it breaks—is no longer niche activism; it is simply smart, evidence‑based consumer behavior.

Additional Resources and How to Stay Informed

To follow ongoing developments, consider:

- Tracking coverage from outlets like The Verge’s right‑to‑repair section and Wired’s right‑to‑repair tag.

- Watching teardown and repair channels on YouTube, such as iFixit and other independent electronics repairers.

- Following policy updates from advocacy organizations and regulators in your region.

When you next upgrade a device, look for:

- Published repairability scores or eco‑labels.

- Transparent software support timelines.

- Clear access to parts, tools, and manuals for out‑of‑warranty service.

These small due‑diligence steps help reinforce market signals that reward companies investing in sustainable, repairable technology.

References / Sources

Further reading and key sources on the mainstreaming of right to repair:

- Wired – Right to Repair coverage

- Ars Technica – Tech Policy and Right to Repair

- The Verge – Right to Repair hub

- Engadget – Right to Repair stories

- TechRadar – Right to Repair news

- iFixit – Introduction to Right to Repair

- U.S. FTC – “Nixing the Fix” report on repair restrictions

- European Commission – Right to Repair initiative