Why Right-to-Repair Is Breaking Open Sealed Tech Ecosystems

The fight over who gets to fix modern electronics sits at the intersection of consumer rights, environmental policy, cybersecurity, and corporate strategy. As right-to-repair laws expand and regulators scrutinize sealed ecosystems, device makers are being forced to rethink everything from how they glue batteries to how their firmware authenticates replacement parts.

In this article, we unpack the technical, legal, and economic forces behind right-to-repair, explore how companies are responding, and examine what this means for the future of smartphones, laptops, game consoles, and connected appliances.

Mission Overview: What Is the Right-to-Repair Movement?

At its core, right-to-repair is about whether you truly own the devices you buy. Advocates argue that ownership must include the ability to:

- Diagnose faults using documentation and diagnostic tools

- Access spare parts at fair prices

- Install those parts without software blocks or legal threats

- Modify and extend devices, within safety and regulatory limits

The opposing model is the sealed ecosystem: hardware is glued, potted, or riveted shut; parts are serialized to specific devices; and firmware refuses to run if it detects “unauthorized” components or repairs. This model has become common in smartphones, laptops, game consoles, tractors, medical devices, and even smart home appliances.

“Restricting consumers and businesses from choosing how they repair products can substantially raise costs while generating harmful waste.” — Lina Khan, Chair, U.S. Federal Trade Commission

Background: How We Got Locked Into Sealed Tech Ecosystems

Early personal computers were inherently repairable: components were socketed, standards-based, and documented. Over the past two decades, three trends converged to erode that openness:

- Miniaturization: Thinner, lighter devices incentivized soldered RAM, glued batteries, and tightly stacked boards.

- Software-centric business models: Companies shifted from one-time hardware sales to recurring service revenue and ecosystem lock-in.

- IP and security concerns: Firmware, secure elements, and cryptographic locks were used to protect secrets—and, critics say, to control repair.

Teardown specialists such as iFixit began documenting how new models sacrificed repairability: batteries buried under stretch adhesive, displays fused to glass, and proprietary screws requiring special bits.

As these practices spread from premium phones to midrange and budget devices, frustration grew among consumers, independent repair shops, and even large institutional buyers like schools and hospitals that faced ballooning maintenance costs.

Mission Overview of the Movement: Law, Policy, and Enforcement

Right-to-repair has moved rapidly from fringe proposal to concrete law in multiple jurisdictions. While details vary, most legislation aims to guarantee access to parts, tools, and documentation on reasonable and non-discriminatory terms.

Key Legal Developments (U.S. and International)

- U.S. State Laws: States such as New York, Minnesota, and California have passed electronics right-to-repair statutes covering smartphones, computers, and other digital devices, with phased implementation and carve-outs for sensitive equipment.

- Federal Guidance: In 2021, President Biden’s Executive Order on Promoting Competition directed agencies to tackle repair restrictions. The FTC subsequently issued a policy statement signaling it would scrutinize anti-repair tactics under existing competition and consumer protection law.

- EU Regulation: The European Union has adopted and proposed measures requiring manufacturers to make certain parts available for years after sale, provide repair information to independent shops, and support standardized labelling for repairability and durability.

- Other Jurisdictions: Countries including France and Australia are experimenting with repairability scores, mandatory parts availability, or sector-specific rules in agriculture and consumer electronics.

These rules are now being tested in practice: regulators are asking whether “self-service” programs truly remove barriers or simply repackage lock-in under a friendlier label.

Technology and Manufacturer Responses

As legal and public pressure has mounted, major tech companies have launched a wave of repair-related initiatives. These programs are technologically sophisticated—and often controversial.

Self-Service Repair Platforms

Several smartphone and PC makers now run portals where users can order official parts and rent specialized tools. Example offerings may include:

- Genuine screens, batteries, cameras, and back glass assemblies

- Calibrated torque drivers and adhesive remover kits

- Step-by-step repair manuals and safety instructions

Critics note that these parts often cost nearly as much as factory repairs, and that availability can be limited by region or model generation.

Parts Pairing and Serialized Components

Many modern devices use parts pairing: each critical component (screen, battery, Face ID module, fingerprint sensor, camera) is associated with the device’s logic board via a unique identifier and cryptographic handshake.

After a repair, the device may:

- Display “unknown part” or “non-genuine” warnings

- Disable or degrade certain features (e.g., brightness controls, biometric sensors)

- Require cloud-based authorization or calibration tools accessible only to approved partners

“Pairing parts to a device through software has become the new way of enforcing manufacturer control over a product even after it’s been sold.” — Electronic Frontier Foundation

From a security engineering perspective, pairing can help ensure trusted components and reduce fraud. But when implemented without meaningful third-party access paths, it effectively centralizes all repair authority with the original manufacturer.

Third-Party Repair Networks

Some firms are expanding authorized service provider (ASP) networks, allowing independent shops to:

- Buy genuine parts at wholesale prices

- Access diagnostics and firmware tools

- Undergo training and certification on safe repair practices

However, non-disclosure agreements and data-sharing obligations can limit how transparent these programs are, and many small repair businesses report that margins become unsustainable when bound by OEM pricing structures.

Scientific and Environmental Significance

The environmental argument for right-to-repair is straightforward: extending device lifetimes reduces material extraction, manufacturing emissions, and e‑waste. But to appreciate the impact, it helps to look at the lifecycle of electronics through a scientific lens.

Lifecycle Assessment and E-Waste

Multiple lifecycle assessment studies find that the majority of a smartphone’s carbon footprint is embedded in its production, not its use. Manufacturing involves:

- Mining and refining rare earth elements and metals

- Fabricating semiconductors in energy-intensive cleanrooms

- Global logistics for components and final assembly

Extending a phone’s usable life from 3 years to 5 or 6 years can substantially amortize this initial environmental cost. The same logic applies to laptops, displays, and network equipment.

“From a climate perspective, one of the most effective actions consumers can take is to use digital devices for longer before replacing them.” — International Energy Agency analysis on digitalisation and energy

Design for Repair vs Design for Recycling

There is an active technical debate between optimizing devices for disassembly and repair versus optimizing for high-throughput industrial recycling. Key trade-offs include:

- Adhesives vs screws: Adhesives can improve ingress protection and reduce weight but make field repair harder.

- Modularity: Swappable modules increase part count and may add bulk but greatly improve upgrade and repair options.

- Material mixing: Complex composites are hard to recycle but can yield performance or aesthetic benefits.

Forward-looking standards and regulations increasingly push “design for circularity,” which balances durability, repairability, and end-of-life recyclability rather than prioritizing any single factor.

Security, Safety, and Intellectual Property Debates

Manufacturers often justify restrictive repair policies by pointing to genuine concerns: compromised batteries can catch fire; tampered sensors can cause medical errors; unvetted components may introduce attack surfaces.

Security Concerns

Key arguments from device makers include:

- Biometric modules (face and fingerprint sensors) are part of the device’s secure enclave and cannot be arbitrarily swapped without risking spoofing attacks.

- Radio modules must meet regulatory limits on emissions; uncertified replacements could interfere with critical services.

- Malicious actors could embed hardware implants or “Evil Maid” modifications if repairs are uncontrolled.

Right-to-repair advocates respond that these risks can be mitigated via:

- Licensing and certifying independent repairers who follow documented procedures

- Open, auditable security protocols rather than proprietary black boxes

- Clear regulatory standards for safe repairs, as in the automotive sector

Safety and Liability

Battery failures and thermal runaway incidents are real. Manufacturers fear being held responsible for accidents caused by poor-quality parts or untrained technicians.

A balanced framework would:

- Require independent repairers to meet documented safety standards

- Mandate transparent labelling of genuine vs compatible parts

- Clarify liability so that each actor is responsible for their portion of the work

This is already standard practice in automotive repair and industrial maintenance, demonstrating that safety and openness can coexist.

Repairability Scores, Teardown Culture, and Data-Driven Decisions

Repairability has become a measurable attribute, much like battery life or display quality. Several organizations publish repairability scores that evaluate:

- Ease of opening the device without damage

- Modularity of core components (battery, display, ports, cameras)

- Availability of parts, manuals, and diagnostics

- Need for proprietary tools or software authorization

These scores increasingly influence:

- Procurement policies in schools and government agencies

- Consumer purchase decisions among tech-savvy buyers

- Design roadmaps inside hardware companies

Online teardown culture—popularized by outlets like iFixit, YouTube repair channels, and communities on Reddit and Hacker News—has turned hardware internals into a public spectacle and an accountability mechanism.

Milestones in the Right-to-Repair Journey

The trajectory of right-to-repair can be traced through several high-profile milestones where public pressure, lawsuits, and regulatory actions converged.

Selected Milestones

- Early Activism: Independent repair shops and online communities document repair roadblocks and share “unofficial” fixes.

- Tractor and Agricultural Battles: Farmers challenge software locks on heavy machinery, arguing that downtime during harvest season can be financially devastating.

- FTC and Competition Authorities: Competition regulators begin to identify repair restrictions as potentially anti-competitive behavior.

- First General Electronics Laws: States and countries move from sector-specific rules (e.g., auto) to broad digital device rights.

- Corporate Self-Service Programs: Major brands introduce consumer repair portals, signaling that fully sealed ecosystems are politically and commercially risky.

Each milestone has shifted expectations: what once seemed radical—publishing a full service manual, for example—is increasingly viewed as table stakes.

Challenges: Technical, Economic, and Legal Frictions

Even with growing support, right-to-repair faces non-trivial challenges that engineers, policymakers, and businesses must solve.

Technical Challenges

- Maintaining performance while improving modularity: Designers must reconcile water resistance, structural integrity, and RF performance with user-serviceable parts.

- Secure yet open diagnostics: Creating diagnostic and calibration tools that are accessible without enabling fraud or malware injection.

- Firmware support longevity: Ensuring that older devices remain fully functional—and securely patched—after repairs and OS updates.

Economic Challenges

- Revenue models: Companies fear losing lucrative repair and upgrade revenue streams.

- Inventory and logistics: Maintaining spare parts availability for many years adds cost and complexity.

- Quality control: OEMs worry about brand damage from poor-quality third-party repairs being blamed on the original product.

Legal and Regulatory Challenges

- Harmonizing state, national, and regional laws to avoid a patchwork of conflicting requirements

- Balancing TRIPS and IP protection with competition and consumer protection law

- Defining clear safe harbors for security research, reverse engineering, and interoperability work

“We’re not asking for the right to do unsafe things — we’re asking for the information and tools necessary to do safe repairs outside of a monopoly.” — Gay Gordon-Byrne, Executive Director, The Repair Association

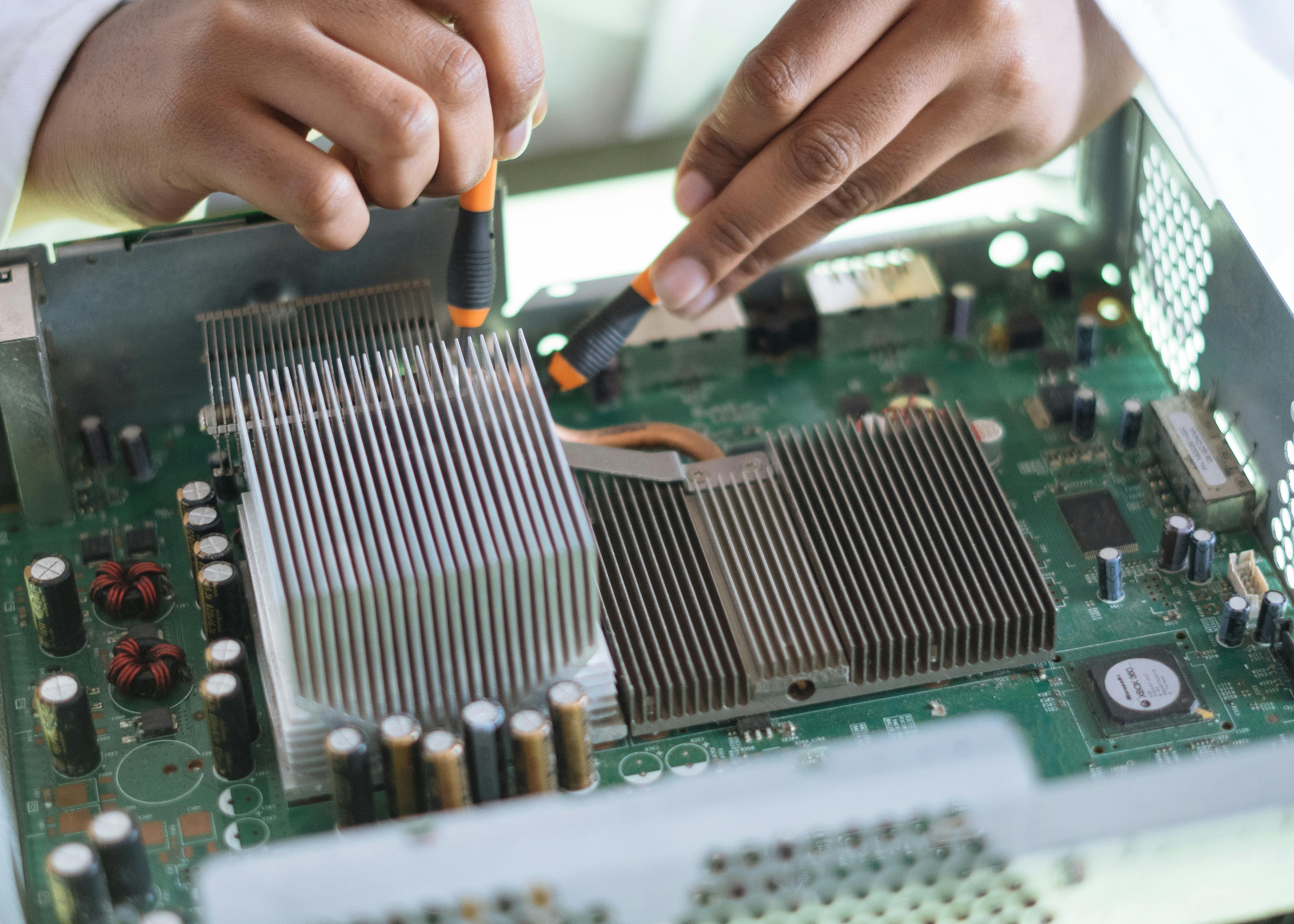

Visualizing the Fight for Repairable Tech

Practical Technology: Tools, Skills, and Learning Resources

For consumers and professionals interested in doing more of their own repairs, a combination of hardware tools, documentation, and training is essential.

Core Tooling for Modern Electronics Repair

- Precision screwdriver sets with Torx, Pentalobe, and tri‑point bits

- Plastic opening picks and spudgers to avoid chassis damage

- Anti-static mats and wrist straps to protect sensitive components

- ESD-safe tweezers and a temperature-controlled soldering station for board-level work

For hobbyists in the U.S., popular kits such as the iFixit Mako Precision Bit Set offer an affordable entry point with a wide variety of specialty bits used in phones and laptops.

Learning Resources

Accessible educational content has exploded alongside right-to-repair interest:

- YouTube channels demonstrating live repairs and board-level diagnostics

- Open service manuals from manufacturers and independent archivists

- Online communities (e.g., r/fixit, specialized Discord servers) for troubleshooting advice

- Vocational training programs focused on electronics and microsoldering

Combining high-quality tools with credible guidance greatly reduces the risk of damaging devices or creating safety hazards during DIY repair.

What Consumers and Organizations Can Do Today

Even while policy debates continue, there are concrete steps individuals and institutions can take to support a more open and sustainable repair ecosystem.

For Individual Consumers

- Consult repairability scores before buying new devices.

- Choose products with replaceable batteries and modular components when possible.

- Back up data regularly to make device servicing and refurbishment safer and easier.

- Use reputable independent repair shops that follow documented safety practices.

For Schools, Businesses, and Governments

- Include repairability and parts availability in procurement criteria.

- Negotiate contracts that guarantee access to parts and documentation for the full expected lifecycle.

- Track total cost of ownership (TCO) including repair, downtime, and replacement cycles.

- Support local repair ecosystems that can maintain fleets of devices efficiently.

Over time, aggregated demand from large buyers may exert more pressure on design decisions than legislation alone.

Conclusion: The Future of Ownership in a Connected World

Right-to-repair is ultimately about clarifying the boundary between the rights of manufacturers and the autonomy of owners in a world where hardware and software are inseparable. As laws tighten and public expectations shift, fully sealed ecosystems that treat users as tenants rather than owners are becoming harder to defend.

The likely end state is not a return to the beige-box PC era, but a more nuanced equilibrium: devices designed for both durability and selective modularity; cryptographic security mechanisms that are auditable and interoperable; and repair markets where OEMs, certified independents, and skilled hobbyists can coexist.

The next decade will reveal whether right-to-repair becomes a default design principle or remains a hard-won exception. For now, the balance of momentum suggests that locked-down devices are on the defensive—and that users will gradually regain more control over the tools that shape their digital lives.

Additional Insights and Emerging Trends

Several emerging technologies may further transform the repair landscape:

- Digital twins for devices: Cloud-based models that track component health and predict failure, enabling proactive repairs instead of reactive replacements.

- Standardized connector ecosystems: Expansion of efforts like USB‑C to internal components (battery, display, cameras) could reduce proprietary fragmentation.

- On-device self-diagnostics: AI-assisted health checks that surface granular error codes and repair recommendations directly to users and technicians.

- Modular compute platforms: Projects exploring upgradeable cores (CPU, RAM, storage) in laptops and even some phones, decoupling performance upgrades from full device replacement.

Staying informed through reputable outlets—such as in-depth reporting from Ars Technica, The Verge, and leading security researchers on LinkedIn and X—can help both professionals and everyday users navigate this fast-evolving space.

References / Sources

Further reading and key sources include:

- FTC – “Nixing the Fix: An FTC Report to Congress on Repair Restrictions”

- The Repair Association – Right-to-Repair Advocacy

- iFixit – Right-to-Repair and Repairability Scores

- European Commission – Right to Repair Initiative

- Electronic Frontier Foundation – Right-to-Repair Issues

- International Energy Agency – Digitalisation and Energy Report