Why Right‑to‑Repair Could Make Your Next Gadget Last Twice as Long

From glued‑in batteries and proprietary screws to software locks that reject third‑party parts, modern gadgets have quietly become harder to fix—even as their price tags rise. At the same time, legislators in the US, EU, and beyond are pushing manufacturers to open up repair documentation, provide genuine parts, and design devices that last longer. This tension has turned right‑to‑repair from a fringe activism topic into a mainstream policy and engineering debate.

Mission Overview: What Right‑to‑Repair Really Means

Right‑to‑repair is both a legal concept and a design philosophy. At its core, it asserts that if you own a device, you should be able to:

- Access manuals and diagnostic information needed to identify faults.

- Buy reasonably priced spare parts and tools, directly or via third parties.

- Replace components—like batteries, screens, and storage—without software blocking or bricking the device.

- Use independent repair shops without voiding essential warranties.

This movement now covers not just phones and laptops, but also tractors, medical equipment, game consoles, and smart home devices. Coverage in outlets like Ars Technica, Wired, and The Verge has helped push the topic into mainstream tech culture.

“If you can’t fix it, you don’t really own it.” — often attributed to repair advocates and popularized by iFixit and other repair organizations.

Background: How We Ended Up with Sealed Gadgets

Early personal computers and feature phones were relatively easy to open and fix. Over time, several forces nudged manufacturers toward sealed designs:

- Miniaturization and thinness: Slimmer devices increase the temptation to glue rather than screw, and to integrate components on a single board.

- Durability and water resistance: Sealed designs make IP ratings easier, but often at the cost of repairability.

- Business incentives: Shorter upgrade cycles and out‑of‑warranty replacements generate repeat sales.

- Software ecosystems: Security mechanisms and paired components are sometimes used to protect users—but also to lock in service revenue.

Critics call this “planned obsolescence,” while many engineers argue that some sealing is a side‑effect of improved performance and robustness. The reality is a mix of both.

Policy Landscape: Laws Pushing for Device Longevity

As of early 2026, right‑to‑repair regulation has moved from proposals to concrete rules in several jurisdictions.

United States: State Laws and Federal Pressure

- Multiple US states, including New York, Minnesota, and California, have passed electronics right‑to‑repair bills targeting consumer devices.

- Laws commonly require manufacturers to provide:

- Service manuals and schematics.

- Diagnostic software and error‑code documentation.

- Spare parts at “fair and reasonable” prices.

- The Federal Trade Commission has signaled support, citing anti‑competitive repair restrictions in its “Nixing the Fix” report.

European Union: Repairability by Design

The EU has gone further with the Right to Repair initiative and Eco‑design rules:

- Mandatory spare‑parts availability for several years after sale (often 7–10 years for major appliances).

- Requirements for user‑replaceable batteries in many portable devices in the coming years.

- Standardized chargers (USB‑C) for phones and small electronics to reduce e‑waste.

These policies directly pressure industrial design teams to prioritize disassembly and component modularity.

Technology: How Design Choices Shape Repairability

The repairability of a device is largely determined at the CAD and PCB layout stage. A few technical decisions have outsized impact:

Fasteners, Adhesives, and Enclosures

- Adhesive vs. screws: Stretch‑release adhesive strips under batteries (as used in some recent phones) can make replacement easier, while solid glue blocks it.

- Standard vs. proprietary screws: Using Torx or Phillips allows broader tool compatibility; pentalobe and tri‑point fasteners intentionally raise the barrier.

- Opening direction: “Top‑down” devices where the display is the first removable part (common in phones) can either simplify or complicate repairs depending on cable routing.

Modularity and Component Integration

High integration improves performance and reduces weight, but hurts repairability:

- Soldered RAM and storage reduce upgrade paths and turn minor failures into full board replacements.

- Modular sub‑assemblies (separate daughterboards for ports, cameras, and speakers) can dramatically lower repair costs.

- Socketed vs. soldered components remain a key debate in laptops and desktops.

Software Locks and Parts Pairing

Increasingly, software decides whether a repair “counts”:

- Parts pairing: Components like screens, batteries, and cameras may require cryptographic pairing to the logic board.

- Calibration tools: Without manufacturer‑supplied utilities, independent shops can’t clear error messages or enable full functionality.

- Remote locks: Devices enrolled in enterprise or MDM programs can restrict third‑party service.

“Modern devices don’t just have hardware serial numbers; they have digital identities embedded deep in firmware. Right‑to‑repair forces us to rethink how those identities are managed.” — paraphrasing commentary from security researchers following coverage in The Verge.

How Tech Media and Influencers Are Shaping the Debate

Teardown culture and repair influencers have made internal design decisions visible to the public.

Teardowns and Repair Scores

Organizations such as iFixit collaborate with media outlets like Engadget and The Verge to:

- Assign numerical repairability scores to new devices.

- Highlight tricky components like under‑display fingerprint sensors and curved screens.

- Call out improvements, such as easier battery swaps or modular USB‑C ports.

Social Media Repair Influencers

On TikTok and YouTube, creators such as mobile repair specialists share:

- Step‑by‑step repairs of cracked screens, batteries, and ports.

- Breakdowns of when official repair programs are necessary vs. DIY options.

- Commentary when apparently minor faults force full device replacement.

Viral videos of pallets of “unrepairable” electronics being shredded have helped push right‑to‑repair into Google Trends and X (Twitter) debates.

Scientific Significance: E‑Waste, Carbon, and Device Lifecycles

Right‑to‑repair is not only about consumer freedom; it’s central to climate and resource policy.

Why Device Longevity Matters for the Planet

- Embodied emissions: A large share of a smartphone’s lifetime CO₂ footprint arises during manufacturing, not daily charging.

- Critical materials: Devices use rare earth elements, cobalt, and other materials with high extraction impacts.

- E‑waste volume: The world generates tens of millions of tons of electronic waste annually, much of it under‑recycled.

Extending device lifetimes by even 2–3 years can significantly cut overall emissions and e‑waste streams. Studies referenced by outlets like Wired and Recode repeatedly show reuse and repair outperforming recycling in environmental benefit.

Intersection with ESG and Corporate Strategy

Investors and regulators now evaluate tech companies on ESG metrics, including:

- Average support window for security and OS updates.

- Availability of certified repair networks and parts.

- Design for disassembly and material recovery rates.

“You can’t credibly claim to be climate‑positive if your core products are disposable by design.” — sentiment echoed in sustainability reports and shareholder letters summarized by Reuters Sustainable Business.

Milestones: How Major Manufacturers Are Responding

Faced with public pressure and looming regulations, several major manufacturers have taken visible steps—though critics question how far they go.

Self‑Service Repair Programs

- Some smartphone and laptop makers now sell official parts, tools, and manuals to individuals.

- These programs often cover screens, batteries, and cameras but still require parts pairing for full functionality.

- Coverage is usually limited to recent flagship models, leaving older devices unsupported.

Standardization and Interoperability

In response to EU mandates and user demand:

- USB‑C has become a near‑universal charging standard on phones, tablets, and many laptops.

- Some vendors are exploring standardized battery packs for certain device classes.

- Industry alliances are discussing common repair data formats and diagnostic protocols.

TechRadar and The Next Web frequently analyze whether these moves represent structural change or are mainly attempts to pre‑empt tougher laws.

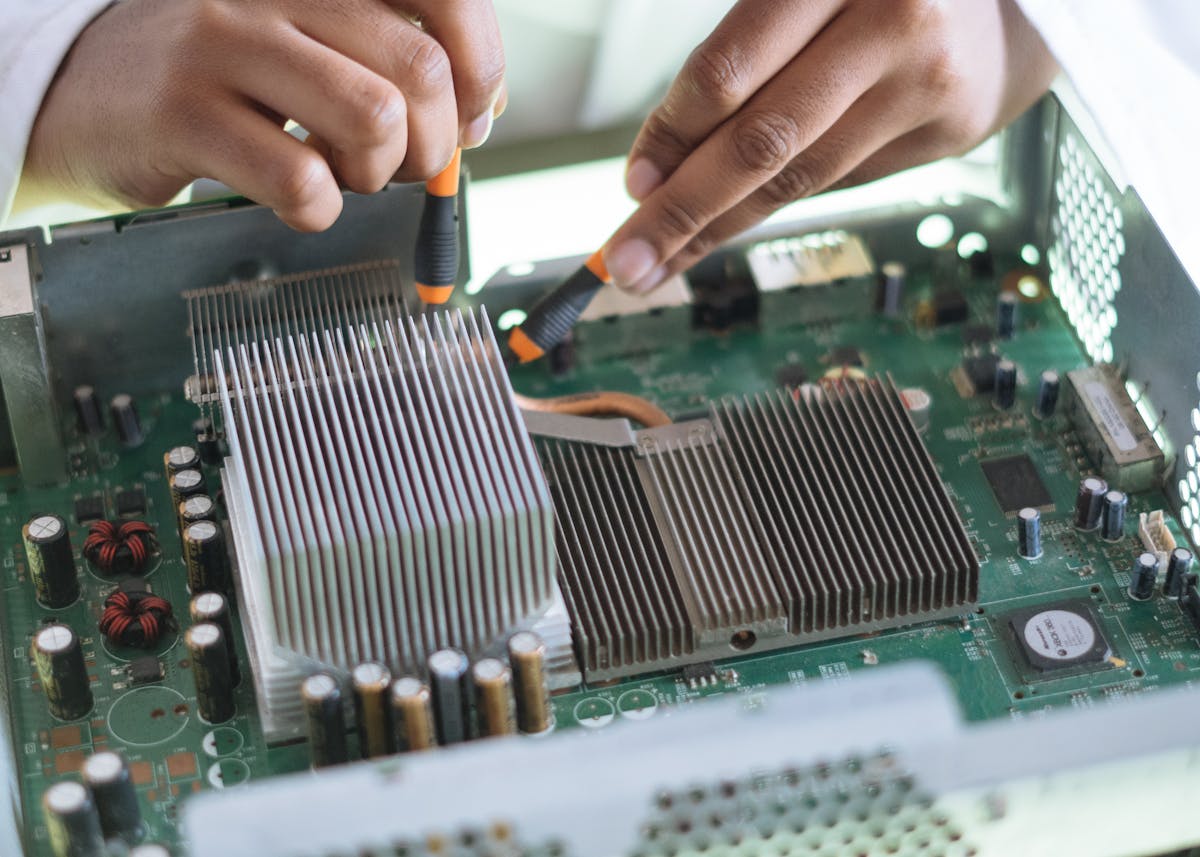

Practical Technology and Tools for DIY Repair

For consumers willing to open their gadgets, the tools and resources available today are better than ever.

Essential Toolkits

A high‑quality electronics toolkit reduces the chance of damage and improves safety. Popular options include:

- iFixit Pro Tech Toolkit — a comprehensive kit with precision bits, spudgers, tweezers, and opening tools widely used by repair professionals.

- ORIA Precision Screwdriver Set — a budget‑friendly alternative suitable for most phone and laptop repairs.

Guides, Communities, and Safety

Before attempting any repair:

- Consult detailed guides on platforms like iFixit and manufacturer help centers.

- Watch multiple teardown videos on YouTube to understand tricky steps.

- Back up your data and, where possible, disconnect the battery early in the process.

- Use ESD (electrostatic discharge) protection for sensitive components.

Challenges: Security, Safety, and Intellectual Property

While many arguments against right‑to‑repair are economic, some concerns are genuinely technical and ethical.

Security and Privacy Concerns

- Supply‑chain attacks: Malicious replacement components could introduce vulnerabilities.

- Data protection: Inadequate handling of user data during repair can lead to privacy breaches.

- Calibration risks: Improper calibration of sensors (e.g., LiDAR, biometric readers) could degrade security.

Security researchers emphasize that these issues are solvable through:

- Strong component attestation protocols with open documentation.

- Secure data‑wipe workflows before repair.

- Certification schemes for independent repair shops.

Safety and Liability

Lithium‑ion batteries, high‑voltage power supplies, and medical or industrial equipment can pose real safety risks if mishandled. Industry groups argue that:

- Manufacturers may face liability for third‑party repair errors.

- Certain calibrations (e.g., for medical devices) must remain tightly controlled.

Modern right‑to‑repair proposals often attempt to carve out exceptions or special regimes for highly safety‑critical categories.

How to Choose Longer‑Lasting, Repairable Devices

Even before regulations fully take effect, consumers can reward companies that design for longevity.

Key Criteria to Look For

- Repairability scores: Check iFixit and European repair indices where available.

- Battery replacement options: Verify whether batteries are replaceable and at what cost.

- Software support window: Look for explicit OS and security update commitments.

- Spare parts catalog: See if parts and manuals are available directly from the manufacturer.

Accessories That Extend Device Lifespan

Simple accessories can significantly reduce wear and damage:

- Rugged cases and screen protectors for phones and tablets.

- High‑quality surge protectors and UPS systems for desktops and NAS devices.

- Well‑ventilated stands or cooling pads for laptops to reduce thermal stress.

For example, a sturdy but slim protective case like the Spigen Tough Armor series can prevent many of the drops that typically send phones to the repair bench.

Conclusion: From Disposable to Durable by Design

Right‑to‑repair, device longevity, and the backlash against sealed gadgets are fundamentally about aligning incentives: between engineers and marketers, between manufacturers and regulators, and between short‑term profits and long‑term sustainability.

As jurisdictions tighten rules and consumers become more discerning, companies that embrace repairability rather than resist it are likely to gain trust and long‑term loyalty. For users, the takeaway is clear: every time you choose a more repairable device, support an independent repair shop, or keep a gadget running for another few years, you’re voting for a more sustainable, user‑centric tech ecosystem.

Additional Resources and How to Stay Informed

To track ongoing developments and deepen your understanding:

- Follow dedicated coverage at Motherboard (Vice) Right‑to‑Repair, Techdirt, and major outlets like Wired and Ars Technica.

- Explore the US Public Interest Research Group (PIRG) Right‑to‑Repair campaign for legislative updates.

- Watch conference talks and debates on YouTube from security and hardware conferences discussing parts pairing and secure repair.

- Consider joining or supporting local repair cafés and community workshops that teach hands‑on skills.

Over the next decade, expect device labels to begin including standardized repairability and support metrics—much like today’s energy‑efficiency labels—making it easier to factor longevity into every tech purchase you make.