Why Right-to-Repair Is Reshaping Tech: Repairability Scores, New Laws, and the Fight for Longer-Lasting Devices

Across the EU, multiple U.S. states, and other regions, regulators now demand access to spare parts, tools, and documentation, while repairability scores from groups like iFixit publicly shame designs that are glued, locked down, or subscription-gated—turning device longevity into one of the defining battles between consumers and Big Tech.

The right-to-repair movement has moved from fringe activism to front-page technology news. What began as a push by tinkerers and independent repair shops is now reshaping global regulation, industrial design, and even how companies talk about sustainability. Major outlets such as Wired, Ars Technica, and The Verge track each new law, teardown, and manufacturer policy change, while social platforms amplify every viral story of a phone or tractor brought back from the dead—or bricked—by a repair attempt.

At the heart of this debate is a simple question with complex consequences: once you buy a device, how much do you truly own it? The answer increasingly determines how long products last, how much e‑waste ends up in landfills, and whether consumers or corporations control the lifecycle of the hardware that runs our lives.

Mission Overview: From Niche Campaign to Global Policy Agenda

Right-to-repair advocates aim to ensure that consumers and independent shops can safely and affordably fix the products they own. In practical terms, this means:

- Guaranteed access to spare parts at reasonable prices.

- Availability of repair manuals, schematics, and diagnostic tools.

- Limits on software locks, parts pairing, and cryptographic restrictions that disable features after unofficial repairs.

- Design incentives for modular, repairable, and upgradeable devices.

“If you can’t fix it, you don’t really own it.” — Kyle Wiens, co-founder of iFixit

What is new since the mid‑2020s is that these goals now have legal backing. The European Union has adopted rules requiring longer support periods and parts availability, while multiple U.S. states—such as New York, Minnesota, Colorado, and California—have passed consumer electronics or sector‑specific right‑to‑repair laws. Similar conversations are underway in Canada, Australia, and beyond.

Regulation: Laws With Teeth and the Rise of Repairability Scores

Right-to-repair regulation varies by jurisdiction, but several common trends are emerging around the world.

Key Legislative Developments

- European Union “Right to Repair” framework

The EU has moved beyond voluntary eco‑design to require:- Longer minimum software and security update windows for smartphones and tablets.

- Mandatory availability of certain spare parts (e.g., batteries, displays) for years after sale.

- Design provisions to enable battery replacement and disassembly without destroying the device.

- Consumer‑facing repairability and durability labeling on product pages and packaging.

- U.S. state laws

Several states have enacted right‑to‑repair laws covering consumer electronics or specific sectors like agricultural equipment and wheelchairs. While details differ, many require OEMs to provide:- Parts, tools, and documentation on “fair and reasonable” terms.

- Parity between authorized and independent repair providers.

- Sector-specific rules

Medical devices, farm machinery, and automotive systems are increasingly covered by tailored regulations balancing safety, cybersecurity, and repair access.

Repairability Scores and Transparency

Alongside regulation, public repairability scoring has become a powerful form of soft pressure:

- iFixit teardown scores rate products from 0 to 10 on repairability, factoring in glue use, modularity, and availability of documentation. These scores are now routinely quoted by outlets like The Verge and Ars Technica.

- French Repairability Index and similar EU labeling schemes force manufacturers to disclose key repair metrics directly to consumers.

Together, regulation and public scoring are moving repairability from a hidden engineering detail to an explicit part of product marketing and comparison shopping.

Technology: Design Choices, Parts Pairing, and Self-Repair Programs

Modern electronics are simultaneously more repairable and more locked‑down than ever. Progress in some areas is offset by new technical barriers elsewhere.

Design for Repair vs. Design for Lock‑In

Engineers juggle multiple constraints: thinness, waterproofing, safety, cost, and aesthetics. Some design patterns matter enormously for repairability:

- Modular components (separate display, battery, camera, ports) make replacement straightforward.

- Standard screws (e.g., Phillips, Torx) beat proprietary screw heads that require specialized bits.

- Clips and gaskets can often replace excessive glue while maintaining water resistance.

- Socketed memory and storage in laptops dramatically extend usable life through upgrades.

Parts Pairing and Software Locks

One of the most controversial technical practices is parts pairing—cryptographically linking components (screens, batteries, cameras) to a device’s logic board. After a repair with non‑paired parts, the system may:

- Show persistent warnings.

- Disable or degrade features (e.g., Face ID, brightness sensors, battery health metrics).

- Refuse to boot or accept updates in extreme cases.

Manufacturers argue that pairing prevents counterfeits and preserves calibration; critics counter that it functionally criminalizes independent repair and undermines the spirit of right‑to‑repair laws.

Official Self-Repair and Authorized Programs

Facing growing legal and reputational pressure, several big brands have launched self‑repair initiatives. These typically include:

- Online storefronts for OEM parts and specialized tools.

- Step‑by‑step repair guides and safety instructions.

- Optional part return programs for responsible recycling.

However, tech media and advocacy groups frequently criticize these programs as partial solutions—expensive kits, limited part catalogs, and continued reliance on software authorization keep many real‑world repairs tightly controlled.

Scientific Significance: E‑Waste, Carbon Footprints, and Lifecycle Analysis

Right-to-repair is not just a consumer rights issue—it is fundamentally a climate and resource question. Electronics generate substantial environmental impacts across their lifecycle:

- Resource extraction for metals, rare earth elements, and plastics.

- Energy‑intensive manufacturing of chips, displays, and batteries.

- Logistics emissions from global supply chains and shipping.

- E‑waste processing, often in poorly regulated conditions.

Multiple life‑cycle assessment (LCA) studies have shown that the majority of a smartphone’s carbon footprint is embedded in manufacturing, not day‑to‑day use. Extending device lifespans by just one or two years can therefore cut total emissions significantly.

“The greenest device is the one you already own—keeping products in use longer is one of the most powerful levers we have to reduce their environmental footprint.” — Paraphrased from circular economy research used by agencies like the IEA and European Commission.

Repair-friendly design and regulation directly support key pillars of the circular economy:

- Refuse & Reduce: Buying less and avoiding unnecessary upgrades.

- Repair & Reuse: Extending functional life through maintenance, part swaps, and refurbishment.

- Remanufacture & Recycle: Recovering high‑value components and materials when repair is no longer viable.

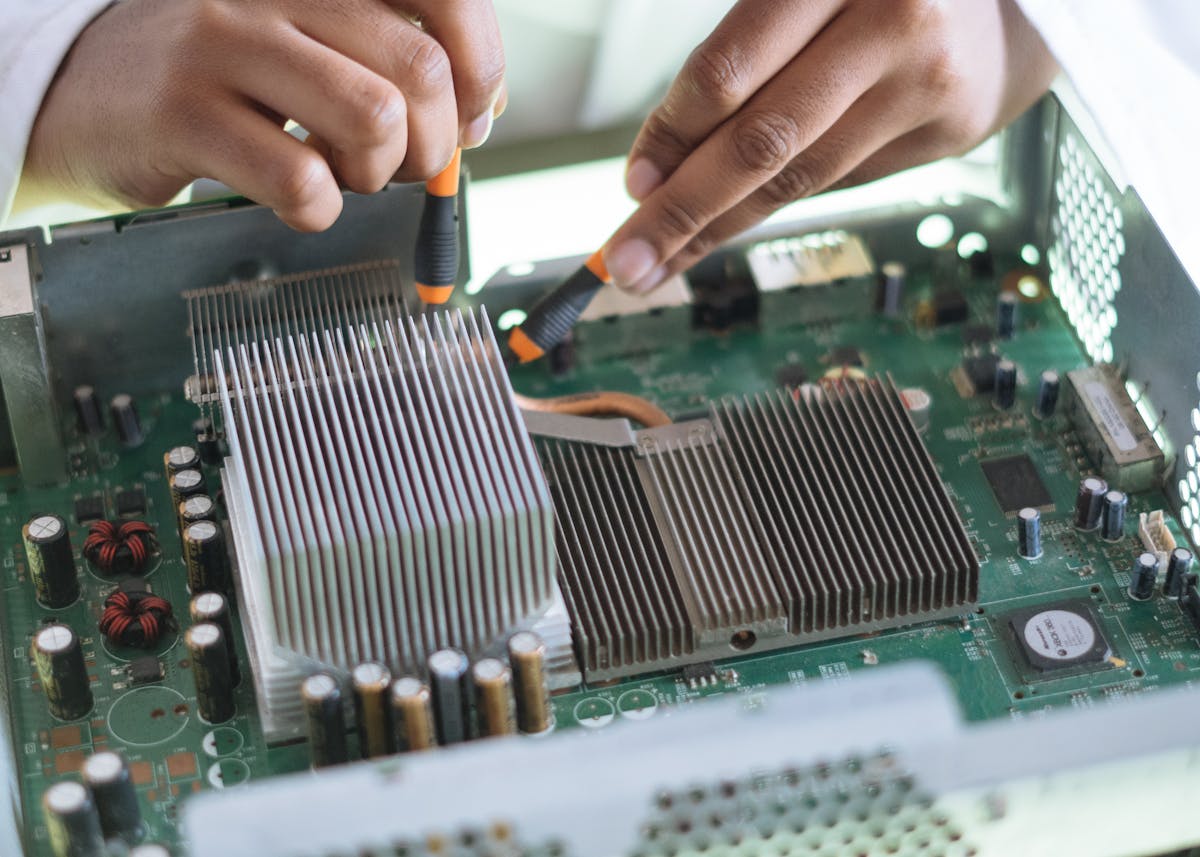

Emerging Repair Ecosystems: Startups, Community Labs, and Tools

Regulation alone cannot deliver repairability; it must be matched by viable ecosystems of tools, skills, and services. In the mid‑2020s, several complementary trends accelerated:

- Refurbishers and recommerce platforms scale professional repair and certification, selling high‑quality used devices with warranties.

- Modular hardware startups design laptops, phones, and accessories with easily replaceable parts and explicit repair rights.

- Community repair events—such as Repair Cafés—teach basic diagnostics and soldering, building local skills.

- YouTube and social media educators publish tear‑downs and live repair sessions, lowering the barrier for motivated DIYers.

Many hobbyists and professionals invest in specialized gear such as hot‑air rework stations, precision screwdrivers, antistatic mats, and microscope cameras. For individual consumers starting out, simpler, safer toolkits are often sufficient.

Helpful Tools and Learning Resources (Including One Amazon Pick)

- iFixit repair guides and community forums provide step‑by‑step instructions and difficulty ratings for thousands of devices (ifixit.com).

- For a reliable starter toolkit, many U.S. hobbyists use the iFixit Mako Precision Bit Set , which covers most smartphone and laptop screws.

- Channels like Louis Rossmann and DIY Perks demonstrate both basic and advanced electronics repair and restoration.

Milestones: How Right-to-Repair Went Mainstream

Several pivotal developments helped turn right-to-repair into a mainstream technology story:

- High-profile advocacy campaigns

Organizations such as The Repair Association and Free Software Foundation Europe’s Right to Repair campaign coordinated policy pushes and media outreach. - Viral teardown culture

iFixit teardowns and Reddit/Hacker News threads made poor repairability scores a reputational liability, especially for flagship smartphones and laptops. - Regulatory breakthroughs

EU eco‑design rules, national right‑to‑repair laws, and landmark state bills in the U.S. showed that political systems were willing to challenge entrenched business models. - Manufacturer policy shifts

Introducing self‑repair programs—even imperfect ones—confirmed that OEMs could open up repairs without collapsing their business. - Public discourse on e‑waste and climate

Coverage from outlets like Wired and Engadget consistently linked repairability to sustainability, embedding the topic in bigger environmental narratives.

Challenges: Safety, Security, and Business Model Tensions

Even supporters acknowledge that right-to-repair raises serious questions that must be handled carefully to avoid unintended consequences.

Safety and Liability Concerns

Modern devices integrate high‑energy density batteries, high‑voltage power supplies, and sensitive sensors. Poorly executed repairs can lead to:

- Overheating or thermal runaway in lithium‑ion batteries.

- Electric shock from exposed power supplies or chargers.

- Compromised structural integrity or waterproofing.

Manufacturers worry about liability for injuries or damage caused by non‑authorized repairs. Advocates argue that clear labeling, training, and documentation are safer than forcing people to rely on guesswork.

Cybersecurity and Privacy

Another concern is that opening up diagnostic ports, firmware tools, and schematics could help:

- Attackers identify vulnerabilities.

- Unauthorized parties tamper with secure elements and authentication hardware.

Thoughtful regulation can remedy this by:

- Requiring traceable access for certain sensitive tools.

- Mandating secure firmware update channels independent of repair access.

- Defining clear responsibilities for repair providers regarding data handling and security.

Business Model Conflicts

Many hardware companies depend on:

- Revenue from authorized repair networks and extended warranties.

- Short upgrade cycles that drive annual or biannual device replacement.

- Subscription and feature lock‑in, tying hardware capabilities to ongoing payments.

Critics argue that some “innovations”—like subscription‑locked heated seats in cars or paywalled smartphone features—are less about technology and more about monetizing artificial scarcity.

“We’ve moved from selling products to selling permission slips to use the things you’ve already bought.” — A frequent critique in right-to-repair and digital ownership debates.

Consumer Backlash: Frustration, DIY Pride, and Social Media Pressure

Online forums and social networks have become the pressure cooker where right-to-repair tensions boil over.

- Reddit and Hacker News frequently feature stories of devices disabled after simple repairs, or of users locked into expensive repair channels.

- YouTube repair videos showcase both successful DIY fixes and cases where OEM policies make simple part swaps unreasonably hard.

- Influential reviewers increasingly factor repairability and update policies into their recommendations.

At the same time, some consumers are wary of self‑repair for understandable reasons: fear of damaging an expensive device, voiding warranties, or triggering safety issues. The most effective messaging emphasizes:

- Choice: People who want professional repair can still use it; others can pick independent shops or DIY.

- Transparency: Clear labeling of difficulty, risk, and required tools.

- Graduated complexity: Encouraging simple repairs (e.g., batteries, fans, SSDs) while cautioning against higher‑risk work without training.

Practical Advice: How to Choose and Care for Repairable Devices

For individual consumers, the biggest leverage often lies in purchasing decisions and basic maintenance. A few practical steps:

Before You Buy

- Check repairability scores from iFixit and, where available, official labels (e.g., France’s repairability index).

- Prefer devices with:

- User‑replaceable or at least serviceable batteries.

- Standard screw types and visible fasteners.

- Upgradeable RAM and storage in laptops and desktops.

- Published support lifecycles (how long security updates are promised).

- Read independent reviews (e.g., from Ars Technica or The Verge) that mention ease of repair.

After You Buy

- Use protective cases and screen protectors to avoid common damage in the first place.

- Keep ventilation slots clear and occasionally clean fans and filters to extend device life.

- Avoid third‑party chargers of unknown quality to reduce risk to charging circuits and batteries.

- Backup data regularly so that if repair goes wrong, you only lose hardware, not information.

When Something Breaks

- Diagnose the problem carefully—software bugs and failing batteries can look similar.

- Check warranty status before opening the device.

- Consult multiple repair quotes, including independent shops.

- For simple issues, follow a reputable guide and use the proper tools.

Conclusion: Who Owns the Future of Our Devices?

Right-to-repair sits at the intersection of engineering, law, economics, and digital rights. New regulations and repairability scores signal that governments and consumers are no longer willing to accept opaque, disposable hardware ecosystems by default.

Over the next decade, the central questions will be:

- Will manufacturers embrace genuinely modular, repairable designs as a selling point, or merely comply at the minimum level?

- Can policymakers balance repair access with legitimate safety and cybersecurity concerns?

- Will consumers reward companies that support long‑term use—and penalize those that prioritize lock‑in?

Device longevity is quickly becoming a litmus test for how seriously the tech industry takes sustainability and user autonomy. The outcome will shape not only our gadgets, but our broader expectations about ownership in a digital, subscription‑driven world.

Additional Resources and How to Get Involved

For readers who want to dive deeper or take action:

- Track legislative updates and advocacy at The Repair Association’s action center .

- Explore teardown data and repair guides at iFixit.

- Learn about EU policy developments via the European Commission’s Right to Repair pages .

- Join or start a local repair meetup through platforms like Repair Café .

Even small steps—choosing more repairable products, learning one basic repair skill, or supporting pro‑repair policies—add up. Collectively, they can tilt the market toward hardware that respects both users and the planet.

References / Sources

- European Commission – Right to Repair: https://environment.ec.europa.eu/topics/waste-and-recycling/right-repair_en

- iFixit – Right to Repair and Teardown Scores: https://www.ifixit.com/Right-to-Repair

- Repair.org – The Repair Association: https://www.repair.org

- Wired – Coverage of Right-to-Repair and Device Longevity: https://www.wired.com/tag/right-to-repair/

- Ars Technica – Hardware and Policy Coverage: https://arstechnica.com/gadgets/

- The Verge – Right-to-Repair Tag: https://www.theverge.com/right-to-repair

- Repair Café International Foundation: https://www.repaircafe.org/en/