Why Right to Repair and USB‑C Standardization Will Decide the Future of Your Devices

Over the last few years, pressure from consumers, regulators, and environmental groups has forced tech manufacturers to rethink one of their most guarded strategies: making devices hard to fix and easy to replace. At the same time, global moves toward USB‑C as a common charging standard are undercutting proprietary connectors that once locked users into a single brand’s ecosystem. Together, right to repair and USB‑C standardization form the front line in a broader fight over device longevity, interoperability, and who truly controls the hardware you own.

Mission Overview: What Is Right to Repair and Why It Matters

The “right to repair” movement argues that consumers and independent shops should be able to fix the products they buy without facing artificial barriers. In practice, it pushes for:

- Access to official repair manuals and diagnostic tools

- Availability of reasonably priced, original or equivalent parts

- Designs that do not deliberately obstruct repair (for example, excessive glue instead of screws)

- Limits on software locks and parts pairing that disable otherwise functional repairs

Governments in the EU, the United States, the UK, and several other regions have introduced or passed legislation that forces manufacturers to open up at least some of these resources—especially for smartphones, laptops, household appliances, and agricultural equipment.

“Restricting consumers and businesses from choosing how they repair products can raise costs, limit options, and shorten the lifespan of devices.” — Lina Khan, Chair of the U.S. Federal Trade Commission

The underlying mission is twofold: extend the useful life of devices and rebalance power between manufacturers and users in favor of ownership instead of rental-like dependence.

Background: From Sealed Gadgets to Repairable Designs

Early personal computers were, by design, repairable and upgradable. Components like RAM, storage, and power supplies were user-swappable. As devices shrank into smartphones and ultra-thin laptops, manufacturers increasingly favored sealed designs to optimize aesthetics, weight, and water resistance.

This design shift has had several consequences:

- Batteries and storage soldered to the board, making replacements difficult.

- Displays fused to glass and digitizers, raising repair costs.

- Custom screws and adhesives that resist disassembly.

- Software-based pairing that rejects replacement parts not “blessed” by the manufacturer.

These changes did improve durability in some ways—particularly resistance to dust and water—but they also accelerated replacement cycles, contributing to rising e‑waste and locking customers further into brand ecosystems.

Teardown specialists such as iFixit and reporters at outlets like Ars Technica and The Verge have played a key role in documenting these trends and scoring devices on their repairability.

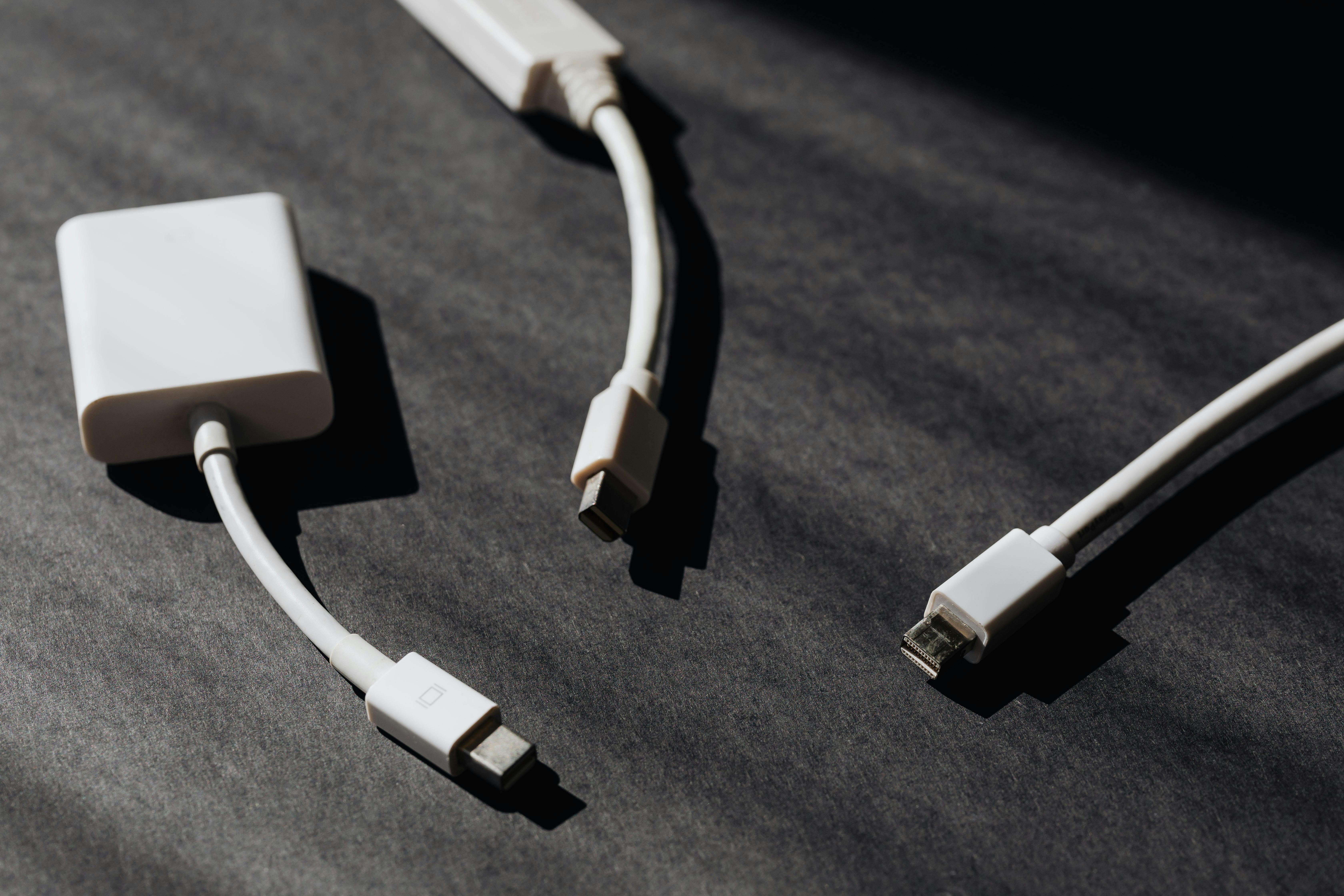

USB‑C Standardization: One Port to Charge (Almost) Them All

USB‑C is a reversible, compact connector designed to handle power, data, and even video through the same physical port. Regulators and standards bodies consider USB‑C a critical lever in reducing cable clutter and e‑waste.

The European Union has led here. Its common charger rules, finalized in 2022 and phased in through 2024–2025, require many categories of consumer electronics—including smartphones, tablets, digital cameras, and more—to adopt USB‑C charging ports. This regulation has already influenced global product lines, since building region-specific hardware variants is costly.

Benefits of USB‑C standardization include:

- Interoperability: The same cable can charge multiple brands and device types.

- Reduced e‑waste: Fewer redundant chargers shipped with every new device.

- Higher performance: Support for fast-charging protocols and high-speed data.

- Accessory longevity: Docks, hubs, and chargers stay useful across upgrades.

However, not all USB‑C implementations are equal. Speeds (USB 2.0, 3.2, 4, Thunderbolt 4), power delivery levels (up to 240 W in the latest USB PD spec), and support for video over USB‑C can vary widely between ports and cables. Review sites such as TechRadar and Engadget now routinely include compatibility charts to clarify what each USB‑C port actually supports.

Technology: How Design Choices Enable or Block Repair

The ease or difficulty of repairing a device flows directly from choices made during industrial design, mechanical engineering, and firmware development. Several recurring design patterns determine whether a product is repair-friendly or hostile.

Modularity vs. Integration

Modular designs separate key components into swappable units: battery, display, camera, storage, and ports. Integrated designs combine many functions into a single board or unit. While integration can improve performance and reduce thickness, it raises repair costs because a failure in one component may require replacing an entire assembly.

Fasteners, Adhesives, and Enclosures

Repairable devices favor:

- Standard screws (e.g., Phillips, Torx) accessible from one side

- Clips and gaskets that can be removed and reused

- Adhesives that soften with heat and do not tear critical flex cables

Aggressively sealed devices may use strong adhesives, permanent rivets, or fused-glass assemblies that are almost impossible to service without specialized equipment.

Software Locks and Parts Pairing

Increasingly, repair barriers are digital rather than physical. Firmware may track serial numbers of critical components such as displays, batteries, and cameras. When a replacement part with a non-authorized serial is installed, the device can:

- Disable certain features (e.g., True Tone or biometric sensors)

- Show persistent warning messages

- Refuse to boot or pass diagnostics

This practice, called parts pairing, is central to current right-to-repair debates. Even when third-party technicians are technically capable of completing a physical repair, firmware can undercut the result.

Official Repair Programs and Tooling

In response to legal and PR pressure, several major manufacturers have launched official self-service repair programs. These typically offer:

- Access to OEM parts and calibration tools

- Detailed service manuals for specific models

- Time-limited rental of professional repair equipment

Coverage from outlets such as Wired and The Verge has highlighted both the promise and shortcomings of these programs—for example, documentation gaps or pricing that makes independent repair less attractive than manufacturer service.

Scientific Significance: Longevity, E‑Waste, and Life‑Cycle Analysis

Right to repair and USB‑C standardization are not only consumer rights issues; they are also engineering and environmental questions that can be quantified with tools like life‑cycle assessment (LCA) and material flow analysis.

Embodied Carbon and Resource Use

Most of a smartphone’s carbon footprint is “embodied” during manufacturing, not operation. Studies cited by the European Commission and organizations like the Right to Repair Europe coalition show that extending a smartphone’s life by just one or two years can significantly reduce its annualized environmental impact.

Allowing battery, storage, or display replacements instead of full device replacement keeps critical materials—rare earth elements, copper, gold, and high-grade plastics—in use longer.

Standardization and System Efficiency

USB‑C and the USB Power Delivery (USB PD) standard enable smarter, more efficient charging across a wide power range. Instead of owning multiple incompatible chargers, users can invest in one or two high-quality, high-wattage chargers that safely negotiate the right voltage and current for each device.

This reduces:

- Redundant manufacturing of low-power “in-box” chargers

- Logistics emissions from shipping millions of extra chargers

- Household-level energy waste from poor-quality adapters

“Improving the durability, repairability and energy efficiency of connected devices can substantially curb the sector’s environmental footprint.” — International Energy Agency, on digitalisation and energy demand

Milestones: Key Legal and Industry Developments

The landscape is evolving quickly, with several notable milestones across regions.

Regulatory Milestones

- European Union: Adoption of common charger rules mandating USB‑C for many device categories, plus eco-design regulations requiring improved repairability for certain appliances and electronics.

- United States: Multiple states, including New York, Minnesota, and Colorado, have passed sector-specific right-to-repair laws covering consumer electronics, wheelchairs, and agricultural equipment, while the FTC has pledged more aggressive action against unfair repair restrictions.

- United Kingdom: Post‑Brexit rules have mirrored and expanded on some EU eco-design and repairability requirements for household appliances and are gradually extending to electronics.

Industry Responses

Manufacturers are reacting in a mix of proactive and defensive ways:

- Launching self-service repair programs with parts and manuals.

- Partnering with established repair networks for authorized third‑party service.

- Redesigning devices with slightly more modular internal layouts.

- Lobbying against or seeking to water down legislation they view as overreaching or risky.

Tech journalism—from Wired’s right-to-repair coverage to policy analyses at Electronic Frontier Foundation (EFF)—has been instrumental in tracking these developments and surfacing both progress and gaps.

Economics and Business Models: Will Repairability Hurt Sales?

One of the most contested questions on platforms like Hacker News and The Next Web is whether encouraging repair will cannibalize hardware sales and innovation.

Shorter Upgrade Cycles vs. Customer Trust

From a traditional sales perspective, faster replacement cycles mean more units sold. But the long-term picture is more nuanced:

- Brands that design repairable devices can build strong loyalty and word-of-mouth.

- Professional and enterprise buyers increasingly factor sustainability into purchasing decisions.

- Subscription and services revenue (cloud, app stores, accessories) can decouple profits from raw device volume.

In practice, companies may find that making devices maintainable while upselling premium features, software, and services yields healthier, more stable revenue than simply pushing annual hardware upgrades.

Independent Repair Ecosystems

A robust repair market supports jobs and small businesses, from local repair shops to specialized mail‑in services. YouTube channels featuring detailed teardowns and repair walkthroughs—often with millions of views—have demonstrated the mainstream appeal of repair as both a skill and a form of tech literacy.

Practical Technology: Tools, Cables, and Chargers That Support Longevity

For individual users, choosing the right tools and accessories can significantly extend device life and maximize the benefits of USB‑C standardization.

Repair-Friendly Toolkits

Precision screwdriver sets, spudgers, and ESD-safe tweezers are essential for safe home repairs. High-quality kits provide the bits and tools required for many modern gadgets, including proprietary screw heads.

For example, the iFixit Moray Precision Bit Set is popular among enthusiasts for electronics repair and includes most of the driver bits needed for modern phones and laptops.

USB‑C Cables and Chargers

With USB‑C, cable quality matters. To take advantage of fast charging and high-speed data, look for:

- Certified USB‑C to USB‑C cables rated for 100 W or higher if you use laptops.

- USB‑IF or Thunderbolt certification for high-performance tasks.

- Clear labeling of supported standards (USB 2.0 vs. USB 3.x vs. USB4).

GaN (gallium nitride) chargers are increasingly favored for their compact size and efficiency. A widely recommended multi-port option is the Anker 65W or 120W USB‑C GaN charger, which can safely power laptops, tablets, and phones from a single brick.

Challenges: Security, Safety, and Design Trade‑Offs

Even strong right-to-repair advocates acknowledge that there are real constraints and trade‑offs.

Security and Privacy

Manufacturers argue that some restrictions protect users against:

- Malicious or compromised replacement parts (e.g., hardware implants).

- Unauthorized access to biometric sensors or secure enclaves.

- Data compromise during repair, especially for devices storing sensitive information.

Carefully-designed repair frameworks must balance legitimate security concerns against anticompetitive practices. Cryptographic attestation for certain secure components, strict technician training, and user-controlled data-wipe workflows can mitigate many risks without locking out independent repair.

Waterproofing and Durability

Another common argument is that highly repairable designs compromise ingress protection. It is true that seam lines, gaskets, and removable panels introduce additional failure points. However, engineering techniques—like robust gasket systems and removable yet tightly sealed back covers—show that it is possible to balance IP ratings with accessibility.

Consumer Complexity

USB‑C standardization has simplified ports but introduced confusion around capabilities. Users may own multiple cables that look identical but support drastically different power or data rates. Clearer labeling, better in‑device UI, and smarter negotiation protocols are needed to fully realize the promise of “one port for everything.”

“Standardizing the connector is only step one; the ecosystem around power and data capabilities must be equally transparent.” — Paraphrasing commentary in IEEE Spectrum on USB‑C adoption

Social Momentum: Media, Communities, and Cultural Shift

Social media platforms, forums, and enthusiast sites have transformed repair from a niche hardware skill into a visible expression of digital self‑reliance.

On YouTube, channels focused on electronics repair, teardown analysis, and hardware deep dives attract millions of viewers. Short‑form platforms like TikTok host viral clips of successful DIY repairs, before‑and‑after restorations, and quick tips for common issues such as screen swaps or battery replacements.

Communities on Reddit, Discord, and independent forums share:

- Model-specific teardown photos and cautions.

- Alternative sources for parts and tools.

- Collective troubleshooting for obscure hardware faults.

This grassroots knowledge network reinforces formal advocacy work from organizations like iFixit’s Right to Repair campaign, The Repair Association, and digital rights groups such as the EFF.

What Consumers Can Do Today

While policy battles continue, there are practical steps you can take now to align your tech choices with longevity and repairability.

- Check repairability scores from sources like iFixit before buying a new phone, laptop, or tablet.

- Prefer USB‑C devices that adhere to open standards and clearly document supported power/data specs.

- Invest in quality charging gear—a robust USB‑C GaN charger and certified cables often outlast multiple devices.

- Start with safe DIY repairs, such as battery or storage upgrades on devices explicitly designed for it.

- Support local repair shops to keep skills and parts supply active in your community.

- Engage with policy by following updates from advocacy groups and contacting representatives when right-to-repair bills are under consideration.

Conclusion: The Future of Device Longevity

Right to repair and USB‑C standardization are converging forces that challenge the idea of sealed, disposable tech. Legislation is nudging manufacturers toward more open, modular designs and common charging standards, while consumers are signaling that durability, sustainability, and autonomy matter as much as raw specs.

The outcome is not predetermined. Companies could comply minimally, preserving opaque software locks and fragile designs, or they could embrace repairability as a competitive advantage and a pillar of environmental responsibility. Likewise, USB‑C could either become a truly universal, transparent standard or remain a confusing jungle of half‑compatible cables and ports.

As a user, your purchasing decisions, repair habits, and political voice all contribute to which future wins. The more demand there is for devices that are fixable, interoperable, and built to last, the harder it becomes for manufacturers to justify throwaway design.

Additional Resources and Further Reading

To stay informed and go deeper into the technical, legal, and environmental aspects of right to repair and USB‑C standardization, consider exploring:

- iFixit – Right to Repair hub for repairability scores and campaign updates.

- The Repair Association – Take Action for U.S. policy developments.

- Right to Repair Europe / UK initiatives for EU and UK regulation details.

- FTC – Nixing the Fix reports for analysis of repair restrictions.

- USB‑IF for official USB‑C and USB Power Delivery specifications.

- YouTube channels specializing in teardowns and repair tutorials, which demonstrate real‑world techniques and common pitfalls.

References / Sources

Selected sources for concepts and data discussed in this article:

- Ars Technica – Gadgets & right-to-repair coverage

- The Verge – Right to Repair tag

- Wired – Right to Repair reporting

- European Commission – Common charger legislation

- FTC – Statement of Chair Lina M. Khan on the Right to Repair

- International Energy Agency – Digitalisation and Energy

- iFixit – Device teardowns and repairability scores

- TechRadar – USB‑C explainer and device reviews

- Engadget – USB‑C and charging ecosystem coverage