Why Right-to-Repair Is the Next Big Tech Battleground

Around the world, new laws, self-service repair programs, and viral teardown videos are forcing an uncomfortable question into the mainstream: when you buy a device, are you purchasing a product—or merely renting access to a sealed black box that can be taken away the moment something breaks?

The modern right-to-repair movement sits at the intersection of ownership rights, cybersecurity, industrial design, and climate policy. What began as a grassroots campaign led by independent repair shops and organizations like iFixit has become a recurring headline across Ars Technica, Wired, The Verge, and other major tech outlets. Legislatures in the U.S., EU, and beyond are debating how much control manufacturers should retain over parts, tools, and software diagnostics—while consumers increasingly judge brands on how easily their devices can be fixed instead of replaced.

At its core, the debate is simple: if you pay for hardware, should you have the legal and practical ability to repair it, modify it, and keep it working for as long as possible? Beneath that question lie decades of design trends toward thinner, more integrated electronics; new business models built on subscriptions and device lock-in; and urgent pressure to reduce e‑waste and carbon emissions from manufacturing.

“If you can't fix it, you don't really own it.” — Kyle Wiens, CEO of iFixit

Mission Overview: What Right-to-Repair Actually Seeks

Right-to-repair is not about forcing people to repair their own devices; it is about ensuring that those who want to—whether individuals, community repair groups, or independent shops—have a fair chance to do so. Different laws and proposals use different wording, but most revolve around a few concrete rights.

Core objectives of right-to-repair policies

- Require manufacturers to provide spare parts at reasonable prices for a minimum number of years.

- Ensure access to technical documentation such as service manuals, wiring diagrams, and calibration procedures.

- Allow independent repairers to obtain diagnostic tools and software, not just authorized service centers.

- Prevent the use of software locks or pairing (e.g., component serialization) that block third‑party parts by default.

- Promote design for repairability, including modular parts, non‑destructive disassembly, and standardized fasteners.

The policy landscape is diverse. Some U.S. state laws currently focus on consumer electronics, while others extend to farm equipment and medical devices. The European Union’s “right to repair” framework, broadened in 2023–2024, adds explicit incentives for repair over replacement and pushes for availability of spares and documentation for up to a decade for some product categories.

“Repairability is emerging as one of the most effective ways to reduce environmental impacts across a product’s lifecycle.” — OECD environment working papers

Technology: How Design Choices Shape Device Longevity

The fight over repair is ultimately a fight over engineering trade‑offs. Modern devices chase thinness, water resistance, and high performance—often at the expense of modularity and repairability. Teardowns from iFixit and YouTube channels like JerryRigEverything or Louis Rossmann show how small design decisions ripple into big consequences for owners.

Common design constraints affecting repair

- Glued batteries and displays — Adhesives improve rigidity and thinness but make replacements messy, slow, and hazardous.

- Soldered storage and RAM — BGA‑soldered chips save space and improve signal integrity but prevent inexpensive upgrades or replacements.

- Proprietary screws and clips — Non‑standard fasteners deter casual opening and require specialized tools.

- Waterproofing gaskets and seals — IP67/IP68 ratings often rely on glue and tight tolerances that complicate reassembly.

- Security chips and pairing — Secure Enclaves and paired components provide anti‑tamper protection but can also block third‑party repairs.

Software, diagnostics, and the “invisible” lock

Beyond the physical device, software plays a major role. Many modern products—from iPhones and MacBooks to tractors and MRI machines—require proprietary software to:

- Run diagnostics and identify failed components.

- Calibrate or pair new components to the system.

- Reset error codes or safety locks after repair.

When that software is restricted, hardware that is physically repairable becomes practically unrepairable. This is particularly visible in agricultural equipment and medical devices, where manufacturers argue that unauthorized access could compromise safety, emissions compliance, or patient health.

“Software has become the new lock on the toolbox.” — Summary of expert testimony in U.S. right‑to‑repair hearings

How Media, Teardowns, and Social Platforms Shape the Debate

Coverage of right‑to‑repair has matured from one‑off curiosity pieces into a continuous narrative arc. Outlets like The Verge, Ars Technica, and Engadget track each new law, company program, and teardown in a kind of running scorecard of progress and pushback.

Role of teardown culture

Viral teardowns bring an abstract policy debate down to the level of individual screws, cables, and chips. When iFixit assigns a “repairability score” to a flagship smartphone or laptop, audiences immediately grasp whether the device is a friend or enemy of repair.

- Spectacularly repair‑hostile designs – e.g., batteries buried under layers of glue – provoke outrage and memes.

- Genuinely modular, fix‑friendly devices get celebrated and boosted on platforms like Reddit and Hacker News.

- Mid‑range “good enough” scores often kick off nuanced debates about engineering constraints.

Online communities as pressure multipliers

Technical and ideological debates on Hacker News, r/RightToRepair on Reddit, and repair‑focused Discord servers dissect:

- Waterproofing versus easy disassembly.

- Thinness and weight versus physical robustness.

- Security hardware versus long‑term reuse of components.

These discussions often inform journalism: reporters mine threads for expert perspectives and real‑world anecdotes, then feed those back into mainstream coverage. Meanwhile, influencers on Twitter/X and TikTok surface viral personal stories—like a laptop bricked after a minor liquid spill because the official repair quote exceeded the cost of replacement.

“Right‑to‑repair has become a proxy battle over who controls the future of hardware: the people who build it or the people who buy it.” — paraphrased from coverage in Wired

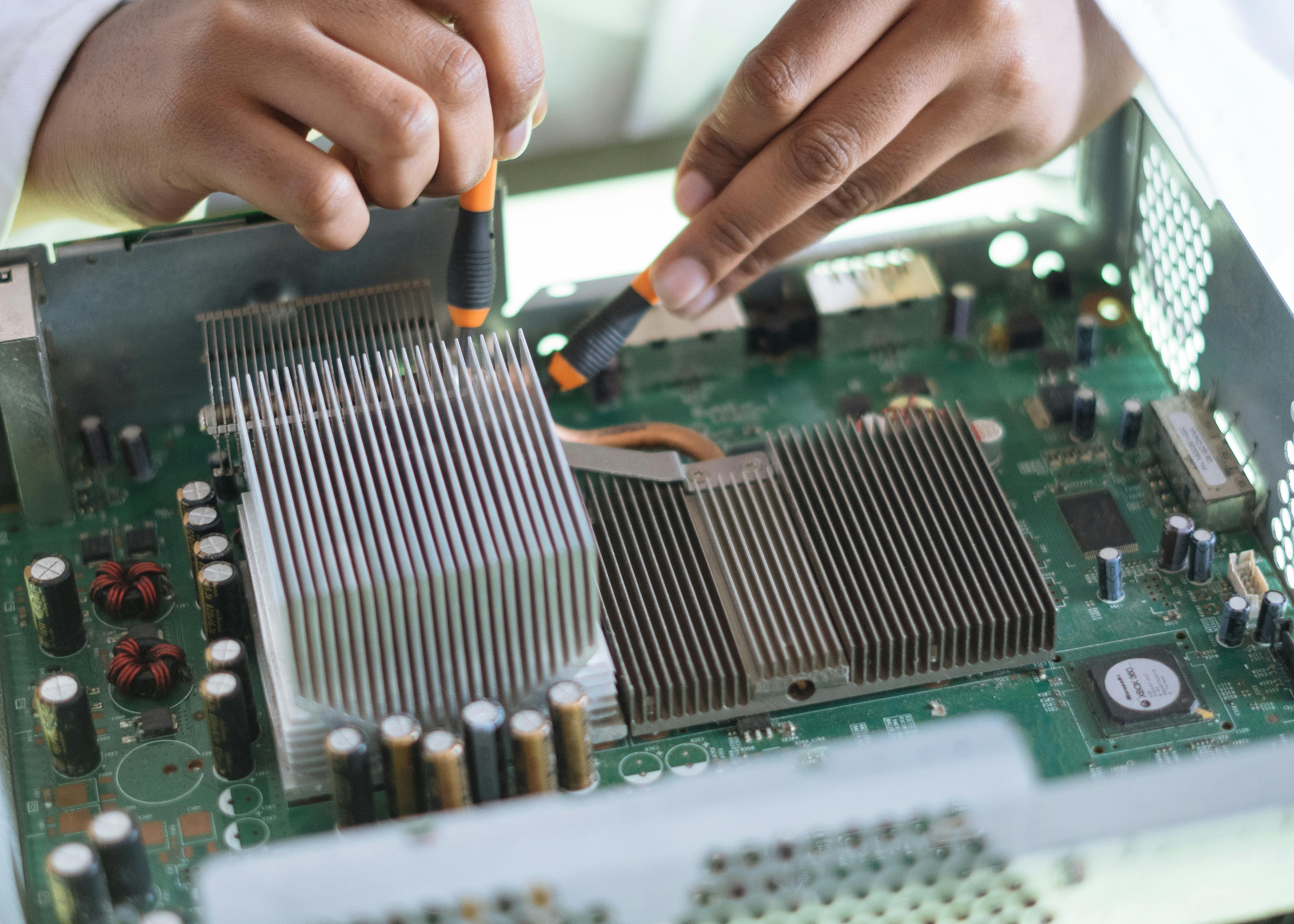

Visualizing the Right-to-Repair Battle

Scientific and Environmental Significance

Device longevity is not only a consumer‑rights issue; it is a measurable environmental and economic problem. The United Nations estimates that the world generates tens of millions of tons of e‑waste annually, much of it improperly recycled or exported to regions with weaker environmental controls.

Lifecycle impacts of repairability

From a lifecycle assessment (LCA) perspective, the majority of a smartphone’s carbon footprint is “front‑loaded” into manufacturing and logistics. Extending the usable life from three to five years can significantly reduce annualized emissions per user.

- Material extraction: Rare earths, cobalt, lithium, and precious metals have high environmental and social costs.

- Manufacturing energy: Chip fabrication and assembly consume large amounts of electricity and water.

- Logistics and packaging: Global shipping and retail distribution add further carbon load.

Right‑to‑repair measures interact with the “circular economy” agenda by making reuse, refurbishment, and remanufacturing more viable. A device with replaceable batteries and standardized fasteners is far easier to refurbish at scale than one designed to be glued shut and discarded at the first major failure.

“Keeping products in use for as long as possible is among the most effective strategies for reducing environmental pressure.” — European Environment Agency on circular electronics

Milestones: Laws, Corporate Shifts, and Public Wins

From 2021 onward, right‑to‑repair has seen rapid momentum across multiple jurisdictions. While exact timelines differ by region, a few milestones stand out as inflection points.

Key policy milestones and trends

- EU Eco‑design and Right‑to‑Repair rules — Progressive regulations expanding repair obligations for appliances, electronics, and eventually smartphones and tablets, including obligations to provide spares and documentation.

- U.S. state‑level legislation — States such as New York, Minnesota, and others have moved forward with consumer electronics right‑to‑repair bills, some covering additional categories like farm equipment.

- Executive and regulatory signals — At various points, U.S. federal agencies and the European Commission have issued guidance encouraging competitive repair markets and warning about anti‑competitive restrictions.

Industry responses and self‑service repair programs

In parallel with legislative action, major tech companies have launched or expanded self‑service repair initiatives. Journalists from Engadget and The Verge have scrutinized these programs, asking:

- Are the parts and tools priced competitively with independent alternatives?

- Are repair guides complete, accurate, and accessible for non‑experts?

- Does the program avoid software pairing traps that effectively require authorized service anyway?

Some initiatives have been praised as meaningful first steps; others are criticized as “PR shields”—too complex or expensive to be useful for most consumers. Nevertheless, their mere existence signals that public and regulatory pressure is working.

Device Longevity, Cost of Ownership, and the User Experience

For everyday users, right‑to‑repair is most tangible as a question of cost, convenience, and trust: how long will this expensive device actually last, and what happens when it breaks?

Hidden costs of non‑repairable designs

- High out‑of‑warranty repair quotes push users to “just buy a new one,” inflating total cost of ownership.

- Data loss risk increases if a device must be fully replaced due to non‑repairable components.

- Geographic inequality arises when authorized service locations are scarce outside major cities.

- Dependence on a single vendor undermines local repair ecosystems and small businesses.

How consumers can vote with their wallets

While legislation moves slowly, buyers can already prioritize repair‑friendly brands and products. Before making a purchase:

- Check the device’s repairability score on iFixit or similar communities.

- Look for modular designs—replaceable batteries, socketed RAM, and M.2 storage in laptops.

- Read warranty and service terms to understand authorized vs. independent repair options.

- Consider refurbished devices from reputable sellers that provide parts and warranty.

For users who want to build basic repair skills, quality tools and guides matter. Entry‑level smartphone and electronics repair kits such as the iFixit Moray Precision Smartphone Opening Toolkit or more complete driver sets like the iFixit Manta Precision Bit Set provide high‑quality bits for common proprietary screws used in phones, laptops, and game consoles.

Challenges: Security, Safety, and Business Models

Right‑to‑repair is not a one‑sided story. Manufacturers and some industry groups raise legitimate concerns about cybersecurity, safety, and liability—issues that lawmakers and advocates must address carefully.

Security and privacy concerns

- Data protection: Poorly vetted repairers could access or mishandle sensitive user data.

- Anti‑tamper systems: Disabling security chips or biometric modules may weaken device integrity.

- Malicious modifications: In critical infrastructure or medical devices, unauthorized changes pose real risks.

Advocates counter that security and repairability can coexist through:

- Clear standards for repairer certification and data handling.

- Hardware‑backed encryption that protects data at rest independent of repair.

- Granular access to diagnostics that does not expose sensitive firmware or credentials.

Economic and innovation arguments

Some companies argue that:

- Repair restrictions protect intellectual property and hard‑won engineering know‑how.

- Integrated designs are essential to deliver cutting‑edge performance and aesthetics.

- Obligatory openness could discourage investment in new product categories.

Critics respond that, historically, open ecosystems have driven robust innovation—citing the PC era, hobbyist electronics, and open‑hardware initiatives. They also emphasize that a significant share of corporate resistance appears tied to revenue from proprietary repair services and accelerated replacement cycles, rather than purely technical concerns.

“There is scant evidence to support manufacturers’ justifications for repair restrictions.” — U.S. Federal Trade Commission report on repair restrictions

Tools, Methods, and the Emerging Repair Ecosystem

As right‑to‑repair gains traction, a parallel ecosystem of tools, educational resources, and business models is emerging to support device longevity.

Common methodologies in modern electronics repair

- Board‑level diagnostics using multimeters, oscilloscopes, and microscopes to identify failed components.

- Micro‑soldering techniques to replace connectors, power‑management ICs, and other surface‑mount parts.

- Reflow and reballing of BGA chips in high‑end repairs, especially on GPUs and SoCs.

- Modular swaps of battery, screen, camera, and storage modules where the design allows.

For advanced hobbyists and professionals, specialized equipment such as hot‑air rework stations, microscopes, and anti‑static setups become essential. For example, many repair technicians rely on compact, temperature‑stable soldering stations like the TS100/TS101‑style portable soldering irons for board‑level work.

Community repair and education

Beyond commercial shops, community‑driven initiatives play a key role:

- Repair cafés and community workshops where volunteers help people fix devices instead of discarding them.

- Online course platforms and YouTube channels that teach step‑by‑step repair skills.

- Open hardware documentation projects compiling schematics, boardviews, and troubleshooting guides.

This educational layer is critical to turning legal rights into practical capabilities. Even with perfect right‑to‑repair laws, devices will not be saved from landfill unless people and businesses know how—and are incentivized—to fix them.

Conclusion: Ownership in the Age of Sealed Devices

Right‑to‑repair is ultimately about modern property rights. As more of our lives run on opaque, software‑controlled hardware—from phones and laptops to tractors, ventilators, and smart door locks—the question of “Who really owns this?” becomes existential rather than academic.

The emerging consensus among technologists, environmental researchers, and a growing share of policymakers is that repairability is not a nostalgic luxury. It is a practical necessity for:

- Reducing e‑waste and carbon emissions tied to new device production.

- Maintaining resilience in critical sectors like agriculture and healthcare.

- Preserving user autonomy and preventing vendor lock‑in.

- Supporting local economies through independent repair businesses.

The next few years will likely determine whether right‑to‑repair becomes a default expectation—baked into design and regulation globally—or remains a patchwork of partial victories. For consumers, staying informed, rewarding repair‑friendly products, and supporting policy efforts will be key levers in tilting that outcome.

“The more control manufacturers exert over your hardware after you buy it, the more important it becomes to push back.” — tech commentary frequently echoed by creators across YouTube and Twitter/X

Practical Next Steps and Further Reading

To go deeper into the right‑to‑repair landscape and make more informed decisions as a consumer, engineer, or policymaker, consider the following actions.

For consumers

- Before buying, check repairability scores and warranty terms.

- Start with low‑risk repairs—like replacing a phone battery or laptop SSD—with clear step‑by‑step guides.

- Invest in a solid tool starter kit such as the iFixit Essential Electronics Toolkit to avoid stripping screws or damaging delicate parts.

For developers and hardware designers

- Incorporate design-for-repairability principles: modular parts, documentation, and non‑destructive disassembly paths.

- Work with security teams to build secure but repairable architectures, separating data protection from hardware lock‑in.

- Engage with open‑hardware and standards bodies to align on interoperable parts and diagnostics where feasible.

For policymakers and researchers

- Study existing legislation outcomes to identify which provisions most effectively increase repair rates without harming safety.

- Support independent research on the environmental and economic impacts of repairability requirements.

- Collaborate with international bodies to reduce regulatory fragmentation for global manufacturers.

References / Sources

Further reading and key resources mentioned or relevant to this article:

- iFixit – Right to Repair overview and campaigns

- Wired – Right‑to‑Repair coverage

- Ars Technica – Right‑to‑Repair articles

- The Verge – Right‑to‑Repair hub

- Engadget – Right‑to‑Repair news

- FTC – “Nixing the Fix” report on repair restrictions (PDF)

- European Environment Agency – Circular economy and electronics

- Right to Repair Europe – Policy updates and campaigns

- Louis Rossmann – Board‑level repair and right‑to‑repair advocacy

- JerryRigEverything – Durability tests and teardowns