Why Right to Repair and Modular Gadgets Are Redefining Consumer Tech

The right‑to‑repair movement has rapidly evolved into a central topic in technology policy, product design, and consumer rights. What began as a grassroots campaign by tinkerers, farmers, and independent repair shops is now reshaping how smartphones, laptops, game consoles, and even kitchen appliances are engineered and serviced.

Tech outlets such as Ars Technica, Wired, The Verge, and TechCrunch now track right‑to‑repair developments as closely as new chip launches or flagship phone releases. At the same time, teardown videos on YouTube and TikTok, community repair cafés, and formal repairability scoring systems are turning “How easy is this to fix?” into a mainstream buying criterion.

“Repair is a fight for the right to extend the lifetime of the things we own.” — Kyle Wiens, co‑founder of iFixit

Mission Overview: What Is the Right to Repair?

At its core, right to repair is the idea that if you buy a product, you should have the practical and legal ability to fix it yourself or choose an independent repair provider. That requires:

- Access to spare parts at fair prices

- Service manuals and diagnostic documentation

- Software tools and firmware that do not block legitimate repairs

- Designs that are reasonably openable without destroying the product

Historically, electronics manufacturers often limited repairs to authorized centers, restricted parts, and used software locks or proprietary screws to deter third‑party servicing. The new wave of regulation and public scrutiny is challenging that model, making repairability a policy issue with economic, environmental, and social dimensions.

Technology, Policy, and Law: How Regulation Is Forcing Change

From 2022 onward, several jurisdictions have enacted or strengthened right‑to‑repair and repairability rules, directly influencing how consumer electronics are designed, labeled, and supported.

Key Legislative Fronts (as of early 2026)

- European Union: The EU’s Ecodesign and Circular Economy initiatives have introduced repairability scoring and minimum parts‑availability periods for categories such as smartphones, tablets, and household appliances. A forthcoming “Right to Repair” directive is expected to tighten obligations on software updates and access to diagnostics.

- United States: Multiple states (including Minnesota, New York, California, and others) have passed or proposed digital right‑to‑repair laws requiring manufacturers to provide parts, tools, and documentation for many electronics. The White House has also signaled support through executive orders encouraging the Federal Trade Commission to curb anti‑repair practices.

- United Kingdom & Commonwealth countries: The UK has adopted repairability‑oriented rules for some appliances and is debating broader digital repair legislation, often referencing EU standards. Australia and Canada have active parliamentary inquiries and draft bills.

These laws influence not just access to parts but also how devices are scored and marketed. Repairability labels—similar to energy‑efficiency ratings—are beginning to appear in online listings and retail packaging, nudging manufacturers to compete on longevity and repair cost.

“Improving product durability and repairability is central to our circular economy ambitions.” — European Commission Green Deal documents

Consumer Awareness and E‑Waste: Why People Suddenly Care

Coverage in Wired, The Verge, TechRadar, and major newspapers has made two ideas widely understood:

- Short‑lived, sealed devices drive massive electronic waste (e‑waste).

- Many “upgrades” are incremental, while the underlying hardware could serve for far longer with simple repairs.

E‑waste is one of the fastest‑growing waste streams globally, with tens of millions of tons generated each year. Batteries glued into phone frames, displays fused to housings, and proprietary parts all make recycling harder and repairs less economical. As climate and sustainability concerns grow, this design philosophy is increasingly viewed as unacceptable.

How Media and Social Platforms Amplify the Issue

- Investigative pieces show how some devices are effectively “disposable” due to repair barriers.

- Teardown videos from creators like JerryRigEverything and repair channels tied to iFixit visually demonstrate hidden glue, fragile cables, and design traps.

- Community repair cafés share success stories where devices get a second life for the cost of a part and a bit of time.

Technology: Modular and Semi‑Modular Gadgets Go Mainstream

Beyond pure policy, a growing class of modular and semi‑modular devices is proving that repairability does not have to mean clunky or outdated. Modern examples range from laptops with standardized, user‑swappable parts to smartphones with user‑replaceable batteries enabled by new regulations.

Defining Modular vs. Repairable Design

- Fully modular: Many key components—battery, storage, RAM, ports, sometimes even CPU modules—can be swapped individually using basic tools.

- Semi‑modular: High‑failure components like batteries and screens are replaceable, while others (e.g., SoC, storage) may still be soldered.

- Repair‑optimized unibody: Devices retain a sleek exterior but are built with pull‑tabs, standardized screws, and modular subassemblies that can be serviced without destructive prying.

Tech reviewers increasingly bake repairability into scoring. Outlets like TechRadar and Engadget now mention how easy it is to open a device, swap a battery, or replace a screen. Meanwhile, iFixit repairability scores are widely cited across tech media, adding a quasi‑standard metric.

Social Media, Teardowns, and Repair Scores

YouTube, TikTok, and forums like Hacker News are critical to how right to repair is perceived. Viral teardowns of a new flagship phone can shape its reputation as much as camera tests or benchmark scores.

Key Dynamics in the Online Ecosystem

- Viral teardown videos: When a phone “fails” a repairability test—e.g., the screen breaks during disassembly or the battery is nearly impossible to remove—the clip becomes a cautionary tale, shared widely across platforms.

- Data‑driven advocacy: Organizations like the Right to Repair Europe coalition and iFixit publish structured ratings and detailed repair guides, which creators reference in their content.

- Technical debate hubs: On Hacker News, engineers and product designers discuss trade‑offs among device thickness, structural rigidity, cost, and repairability—highlighting that this is not a simple engineering problem.

“Designing for repairability is not a free lunch—but neither is designing for disposability once you include environmental and support costs.” — Typical Hacker News commentary on modular devices

Scientific Significance: Sustainability, Lifecycle, and Systems Thinking

While right to repair is often framed as a consumer issue, it is deeply connected to sustainability research, lifecycle assessment (LCA), and circular economy models.

Lifecycle and Environmental Impacts

Studies consistently show that extending the useful life of electronics—by even one or two years—often yields greater environmental benefits than marginal gains in energy efficiency. The most carbon‑intensive phase of many devices is manufacturing, not daily use.

- Producing a new smartphone can emit 50–100 kg of CO₂‑equivalent, depending on the model.

- Extending a laptop’s life from 3 to 6 years can significantly reduce its annualized footprint.

- Repairability directly influences whether users replace or maintain their devices.

Academic work in journals like Resources, Conservation & Recycling and reports from groups such as the OECD and the UN Global E‑waste Monitor underscores that better repair ecosystems are a cornerstone of sustainable electronics.

Economic and Business Implications

Manufacturers historically argued that opening devices to independent repair would compromise safety, reduce reliability, or erode intellectual property. However, new business models are emerging that show repairability can be financially attractive.

Shifts in the Value Chain

- Refurbish and resell: High‑quality used electronics, certified by manufacturers or third‑party refurbishers, have become a robust market. Devices designed for easier part replacement are cheaper to refurbish.

- Subscription and leasing models: Some companies are experimenting with leasing phones or laptops and reclaiming them for repair and redeployment—an approach that aligns naturally with modular design.

- Third‑party repair ecosystems: Independent shops and community repair initiatives thrive when parts and documentation are available, providing local jobs and technical education.

“Right to repair is not just about ethics; it’s about economics. Every device we can fix instead of replace saves raw materials, energy, and money.” — Paraphrased from multiple circular‑economy researchers

Milestones: How Right to Repair Hit the Mainstream

A series of visible turning points helped transform right to repair from niche activism into headline news across major tech outlets.

Notable Developments (2010s–mid‑2020s)

- The growth of iFixit and similar platforms popularized step‑by‑step guides and repair scores.

- Farm equipment repair disputes, notably involving tractors, highlighted the dangers of software locks beyond consumer electronics.

- EU and state‑level US laws introduced formal obligations for parts, manuals, and repairability metrics.

- Major smartphone and laptop makers launched self‑service repair programs, providing official spare parts and tools for select models.

- Reviewers began treating repairability as a core criterion, causing poor‑scoring products to attract negative coverage.

By the mid‑2020s, it became common to see teardown scores, e‑waste data, and policy commentary mentioned in the same breath as chip specs and camera modules in mainstream product reviews.

Challenges: Firmware Locks, Parts Pairing, and Thinness Obsession

Despite clear momentum, several technical and policy obstacles could limit the impact of right‑to‑repair reforms.

Technical Barriers

- Parts pairing: Some manufacturers cryptographically pair components (such as screens or batteries) to a device’s mainboard. Replacements must be “authorized,” or features may be disabled, which can block independent repair even when a physical repair is straightforward.

- Firmware locks and remote diagnostics: Secure boot chains and remote verification systems can be used for security and anti‑theft—but can also, intentionally or not, exclude third‑party repairers from running calibration or configuration tools.

- Design trade‑offs: Pushing devices to be ever thinner often requires glue instead of screws, stacked boards, and fragile connectors, all of which reduce repairability.

Regulatory and Market Gaps

- Scope limitations in laws leave some product categories unprotected.

- Conflicts between trade‑secret protections and documentation disclosure remain unresolved.

- Consumers still frequently prioritize aesthetics and raw performance over long‑term maintainability at purchase time.

These tensions are at the center of ongoing debates among policymakers, engineers, and right‑to‑repair advocates. Finding balanced solutions—where security and sustainability reinforce rather than undermine each other—will be a major design and regulatory challenge in the coming years.

Practical Guidance: How Consumers Can Support Repairable Tech

For individual buyers, supporting right to repair mostly means making informed choices and planning for maintenance from day one.

Steps You Can Take

- Check repairability scores and teardown reports before buying new devices.

- Prefer products with user‑replaceable or at least easily serviceable batteries.

- Store receipts, serial numbers, and warranty details in a secure location to facilitate future repairs.

- Use protective cases and screen protectors to reduce the likelihood of catastrophic damage.

- Choose reputable third‑party or manufacturer‑certified repair centers instead of discarding devices prematurely.

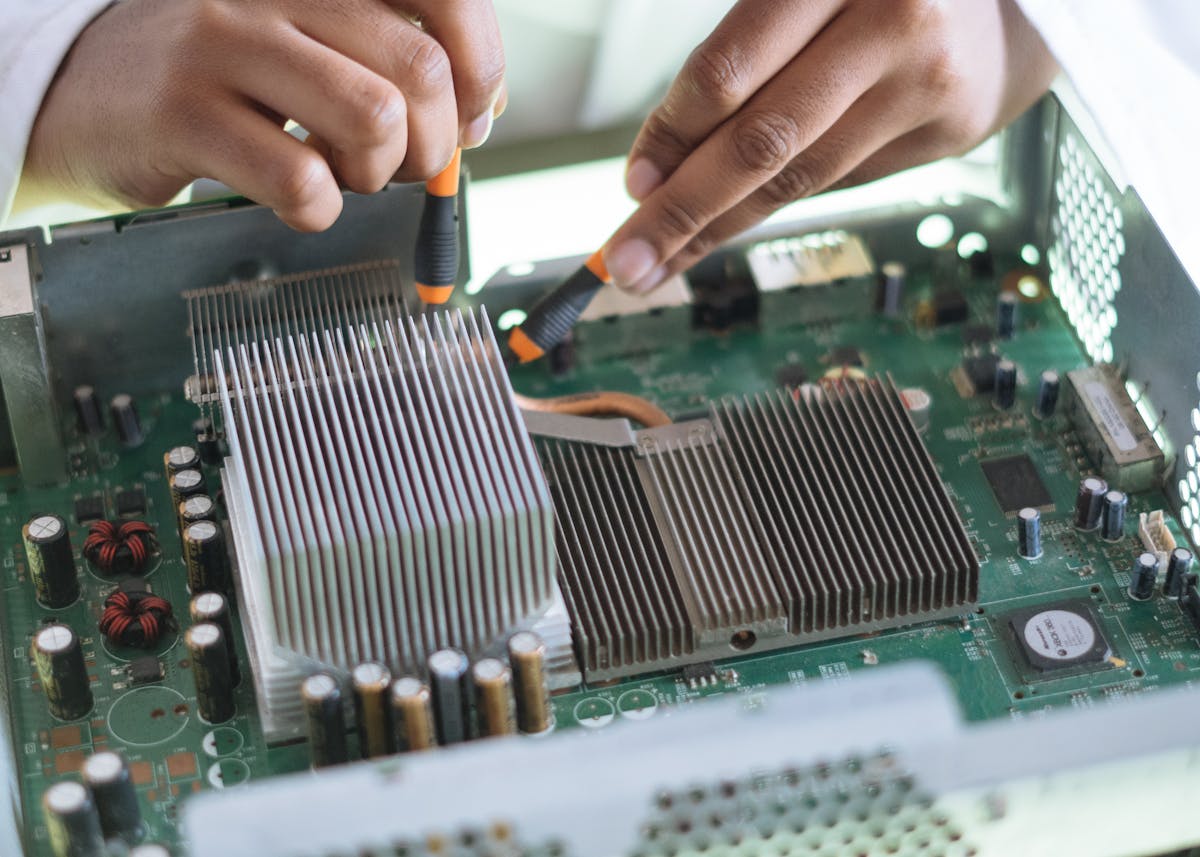

Investing in basic repair‑friendly tools can also make a significant difference. Precision screwdriver kits, antistatic mats, and spudgers are inexpensive and widely recommended in repair guides.

For example, many repair professionals and hobbyists rely on high‑quality precision screwdriver sets similar to the 120‑in‑1 precision electronics repair kit , which includes multiple bit types compatible with phones, laptops, game consoles, and small appliances.

Future Directions: Smarter Modularity and Circular Design

Looking ahead, mainstream gadgets are likely to incorporate more modular features and life‑cycle‑aware design choices without necessarily becoming “fully modular” in the classic sense.

Emerging Trends to Watch

- Standardized battery formats: Under EU rules, user‑replaceable batteries in smartphones and other devices are re‑emerging, pushing manufacturers to rethink internal layouts and sealing methods.

- Modular I/O and accessory ecosystems: Swappable ports, expansion cards, and magnetically attached peripherals enable customization without replacing core hardware.

- Design for disassembly: Engineers incorporate labeled pull‑tabs, color‑coded connectors, and modular subassemblies that can be removed with minimal steps.

- Digital twins for devices: Cloud‑based maintenance logs and digital service histories may help track component health and inform repair vs. replace decisions—if implemented in an open, user‑centric way.

Conclusion: From Regulatory Threat to Competitive Advantage

Right to repair is no longer a peripheral issue; it is becoming a defining characteristic of responsible, future‑ready technology companies. As more jurisdictions adopt repair‑friendly laws and more consumers factor longevity into their buying decisions, repairability is shifting from a perceived regulatory burden to a market differentiator.

Manufacturers that embrace modularity, transparent documentation, and fair access to parts can benefit from:

- Reduced reputational risk and regulatory friction

- New revenue streams via refurbishment, certified used markets, and extended service plans

- Stronger brand loyalty from consumers who value ownership and sustainability

For policymakers and researchers, right‑to‑repair offers a practical lever to reduce e‑waste, improve resource efficiency, and create local repair economies. For consumers, it restores a sense of agency: the ability to maintain and extend the life of the tools we rely on daily.

Additional Resources and Further Reading

To dive deeper into the technical, legal, and environmental aspects of right to repair and modular design, consider exploring the following resources:

- iFixit – Right to Repair overview and advocacy hub

- Right to Repair Europe – Policy updates and campaigns

- Wired – Right to Repair coverage

- The Verge – Right to Repair news and analysis

- YouTube – Right to Repair documentaries and talks

For technical audiences, standards on ecodesign, lifecycle assessment, and electronics recycling from bodies like ISO, IEC, and the IEEE provide deeper frameworks for embedding repairability into engineering practice.