Why Right‑to‑Repair Is Reshaping the Future of Our Gadgets

Once a technical curiosity discussed on repair forums and small policy panels, the right‑to‑repair movement is now a core issue in global tech culture. From iPhones and gaming laptops to tractors and washing machines, escalating fights over repairability, parts access, and software locks are driving sustained media coverage and grassroots activism. At its heart lies a simple question with far‑reaching consequences: when you buy a device, do you truly own it—or are you merely licensing a sealed service you are not allowed to open?

Over the past year, mainstream outlets such as Ars Technica, The Verge, Wired, and Engadget have covered legislative developments, corporate policy shifts, and high‑profile repair wins and failures with increasing intensity. Meanwhile, YouTube channels like iFixit and repair advocate Louis Rossmann have turned teardowns and diagnostics into viral content, galvanizing a global community of tinkerers and concerned consumers.

Mission Overview: What Is the Right‑to‑Repair Movement?

The right‑to‑repair movement advocates for legal and practical guarantees that consumers and independent technicians can fix the products they own without unreasonable barriers. In practice, this mission breaks down into several concrete demands:

- Access to spare parts at fair prices, including batteries, screens, sensors, and mechanical components.

- Availability of service manuals, schematics, and diagnostics comparable to what authorized service centers receive.

- Designs that prioritize repairability—for example, fewer glued‑in components and more standard fasteners.

- Restrictions on software locks and parts pairing that prevent functional repairs with compatible components.

- Policies that preserve data security and safety while not being used as a pretext to block legitimate repairs.

“If a company can stop you from fixing something you bought, you don’t own it—it owns you.” — paraphrasing a widely shared sentiment among right‑to‑repair advocates

While the basic idea seems intuitive, it clashes with business models that rely on proprietary ecosystems, captive service networks, and rapid replacement cycles. As a result, right‑to‑repair has become a fault line between consumer interests, corporate strategy, and environmental responsibility.

Legislative Momentum Around the World

Over the last few years—especially through 2023–2024—right‑to‑repair has turned into a serious legislative agenda item in the United States, the European Union, and beyond. Each new bill has triggered waves of analysis and lobbying from tech giants, farm equipment manufacturers, and advocacy groups.

United States: State‑Level Breakthroughs

In the U.S., federal policy still lags, but statehouses have become active battlegrounds:

- New York’s Digital Fair Repair Act – One of the earliest comprehensive right‑to‑repair laws for consumer electronics, requiring manufacturers to provide parts, tools, and documentation for certain products sold in the state. Implementation details and carve‑outs have been controversial and closely reported on by outlets like The Verge.

- California’s Right‑to‑Repair Law (SB 244) – Passed in 2023, it compels manufacturers of many electronic devices to offer parts, tools, and documentation for several years after a product’s release, aligning closely with the demands of advocacy groups like U.S. PIRG.

- Colorado’s Agricultural & Wheelchair Laws – Colorado has led in non‑consumer electronics, passing laws that guarantee farmers and wheelchair users access to diagnostics and repair resources, a direct response to long‑standing conflicts with companies such as John Deere.

According to The Repair Association, dozens of additional state bills have been introduced or drafted, covering everything from smartphones and appliances to medical equipment.

European Union: From Repairability Scores to Legal Obligations

The EU has taken a more centralized and systematic approach:

- Eco‑design regulations that require longer support periods and easier battery replacement for certain categories of electronics and appliances.

- Repairability labeling initiatives—France already uses a repairability score, and EU‑wide versions are being piloted.

- Ongoing work on a “Right to Repair” directive that would give consumers stronger legal options to demand repair instead of replacement under warranty and post‑warranty contexts.

These policy moves ripple out globally: manufacturers typically prefer not to maintain vastly different designs for each region, so EU rules often become de facto global standards for repairability and sustainability.

High‑Profile Corporate Shifts in Repair Policy

Under growing regulatory pressure and public scrutiny, several major tech companies have moved—sometimes reluctantly—toward more repair‑friendly policies. These shifts, however imperfect, demonstrate that industry norms are no longer static.

Apple and the Self Service Repair Program

Apple, long criticized for glued‑in batteries and proprietary screws, has drawn particular attention. Its Self Service Repair program, launched in the U.S. and later expanded to multiple countries, allows customers to rent professional‑grade tools and purchase genuine parts for iPhones, Macs, and some other devices.

While advocates welcomed the move as a proof of concept, they also point out significant limitations:

- Repairs often remain complex and risky for non‑experts.

- Parts pricing and required deposits can make official repairs economically unattractive.

- Parts pairing and software calibration steps still tie functionality to Apple’s cloud and tools.

Reviews from The Verge and others concluded that the program is better suited to experienced technicians than typical users, but it sets an important precedent that manufacturers can safely open their ecosystems to more repair.

Repair‑Friendly Innovators: Framework and Fairphone

In contrast to legacy giants, companies like Framework and Fairphone have built their brands around repairability:

- Framework laptops feature modular mainboards, easily replaceable ports, and standardized fasteners. Outlets such as Ars Technica and TechRadar highlight them as proof that modern performance and sleek design can coexist with high repairability.

- Fairphone provides easily swappable modules—camera, battery, USB‑C port—and long‑term software support, showing that smartphones need not be disposable.

“We started Framework to prove that you can build products that are high‑performance, beautiful, and also designed to last.” — Framework team statement

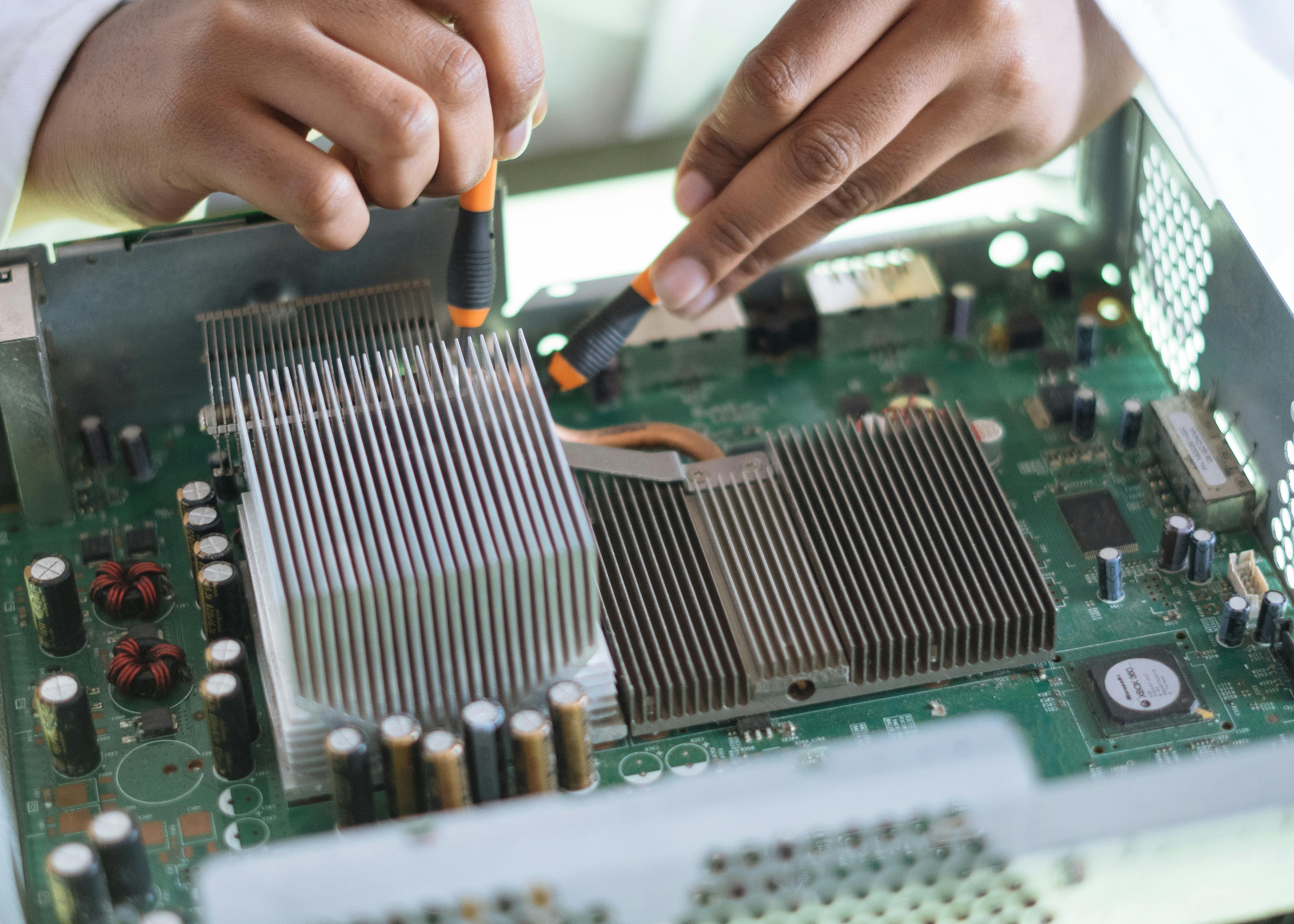

Technology: How Sealed Gadgets and Software Locks Work

To understand why right‑to‑repair is contentious, it helps to unpack the technical mechanisms that make many modern devices difficult—or impossible—to fix outside authorized channels.

Physical Barriers: Glue, Proprietary Screws, and Integrated Assemblies

Many gadgets use adhesives instead of screws to secure batteries, displays, and cases. From a manufacturer’s point of view, this can:

- Save manufacturing time and cost.

- Improve water resistance and thinness.

- Discourage tampering.

But for repairers, heavy use of glue means:

- Increased risk of damage during disassembly.

- More labor‑intensive repairs requiring heat, solvents, or specialized tools.

- Reduced chances that end users can carry out safe do‑it‑yourself fixes.

Similarly, proprietary screw heads (such as tri‑point or pentalobe designs) and tightly integrated assemblies (where a cracked glass forces full display replacement) limit what can be repaired affordably.

Software Locks and Parts Pairing

Physical access is only half the story. Increasingly, device functionality depends on cryptographic checks between hardware components and firmware. This is often called parts pairing or serial‑number locking.

Typical mechanisms include:

- Component serialization – Each part (battery, camera, screen) has a unique ID stored in firmware.

- Calibration or activation tools – After replacement, the device runs a software routine—often proprietary—to register the new part.

- Feature gating – If the part ID is not recognized or not registered through official tools, the device may disable certain capabilities (like True Tone, Face ID, advanced camera features) or show warning messages.

Manufacturers defend these approaches as necessary for quality control, user security, and anti‑counterfeiting. Critics counter that the same techniques can be, and frequently are, used to shut out independent repair shops and force consumers to use expensive official services.

“Software locks have become the new screws. You can open the device, but that doesn’t mean it will accept the repair.” — iFixit commentary on parts pairing

Diagnostics, Telemetry, and Data Lock‑In

Modern devices also depend heavily on software diagnostics and cloud‑based services:

- Embedded diagnostics that only authorized tools can access.

- Remote telemetry used to flag unofficial components as “non‑genuine.”

- Cloud accounts that can render devices un‑usable if not properly transferred or reset.

These systems have legitimate uses for security and fleet management, but they also shift power away from the user and toward the manufacturer, complicating independent repair and refurbishing.

Scientific and Societal Significance: E‑Waste, Economics, and Ownership

Right‑to‑repair is not just a consumer convenience issue; it has profound implications for environmental science, resource management, and digital rights.

Environmental Impact and E‑Waste

The World Economic Forum and the United Nations have repeatedly warned that electronic waste (e‑waste) is one of the fastest‑growing waste streams in the world. Discarded electronics contain:

- Valuable metals like gold, copper, and rare earth elements.

- Toxic substances such as lead, mercury, and brominated flame retardants.

Extending device lifetimes through repair directly reduces the throughput of this waste stream. Studies summarized by the OECD and EU agencies show that:

- Repairing or refurbishing devices significantly lowers lifecycle CO₂ emissions compared with manufacturing replacements.

- Battery replacement alone can extend smartphone lifetimes by years, delaying resource‑intensive production.

Economic and Social Dimensions

On the economic side, right‑to‑repair:

- Supports local repair businesses and community repair cafés.

- Reduces the financial burden on households that cannot frequently upgrade devices.

- Creates secondary markets for refurbished devices, improving digital access for lower‑income users.

This is particularly crucial in education, where keeping older laptops and tablets functional can make a direct difference in students’ learning opportunities.

Ownership, Autonomy, and Digital Rights

Beyond economics and carbon, right‑to‑repair touches on philosophical and legal questions of ownership and autonomy:

- Do you own a product if its functionality remains under remote control or license terms that can change after purchase?

- How should the law balance intellectual property rights with the user’s right to open, modify, and repair a device?

- What happens when essential tools—like farm equipment or medical devices—are locked behind proprietary service agreements?

Debates on Hacker News frequently dissect these questions, treating right‑to‑repair as part of a broader struggle over user agency in a networked world.

Key Milestones and Recent Developments

Over roughly the last decade—and especially in the last few years—several milestones have propelled right‑to‑repair from fringe to mainstream.

Notable Milestones

- 2010s: iFixit Scores and Teardowns – iFixit’s repairability scores and step‑by‑step guides helped quantify how repair‑friendly devices are and gave consumers a new factor to weigh in purchase decisions.

- 2018: U.S. FTC Workshop and Reports – The Federal Trade Commission began examining manufacturer repair restrictions, later concluding that many justifications for opposing independent repair were unsubstantiated.

- 2021–2023: State‑Level Bills and EU Actions – A wave of U.S. state bills and EU initiatives made “right‑to‑repair” a recurring headline topic, especially whenever high‑profile manufacturers lobbied for exemptions.

- 2023–2024: Apple, Microsoft, and Others Expand Repair Programs – Corporate self‑service programs, while imperfect, signaled a shift in tone and an acknowledgement that user demand for repair is not going away.

Media and Community Activism

Parallel to legislative and corporate moves, grassroots and media activism played a crucial role:

- YouTube channels like Louis Rossmann’s and iFixit’s turned device teardowns into educational activism, exposing anti‑repair tactics and demonstrating best‑case repair practices.

- Social media campaigns on X/Twitter, Reddit, and TikTok amplified stories of successful repairs and frustrating corporate roadblocks, bringing laypeople into the conversation.

- Coverage from outlets like Wired and Engadget consistently linked repairability to broader themes of sustainability and consumer choice.

Together, these threads created a feedback loop: policy news drove coverage, coverage fueled activism, and activism pushed new policy proposals.

Challenges and Counter‑Arguments

Despite clear momentum, the right‑to‑repair movement faces significant technical, legal, and political hurdles. Understanding these challenges is crucial for crafting effective, balanced policy.

Security and Safety Concerns

Manufacturers often argue that loosening repair restrictions could compromise:

- Cybersecurity – Poorly performed repairs might introduce vulnerabilities or allow tampering with secure elements.

- Physical safety – Lithium‑ion batteries can be dangerous if damaged or improperly installed, and repairs to medical devices or vehicles carry obvious safety implications.

Most right‑to‑repair advocates acknowledge these concerns but argue that:

- Safety can be addressed via training, standards, and disclosures rather than blanket restrictions.

- Authorized service centers are not risk‑free; independent shops often match or exceed their quality.

Intellectual Property and Trade Secrets

Another frequent argument is that providing schematics, firmware access, or proprietary tools risks exposing trade secrets or enabling low‑quality knockoffs. Policymakers must carefully define:

- What documentation and tools are reasonably necessary for repair.

- How to prevent those materials from being repurposed for large‑scale counterfeiting.

Economic Incentives and Business Models

Many current business models rely on:

- Planned or perceived obsolescence to drive frequent upgrades.

- Captive service networks that generate predictable revenue.

- Lease‑like relationships where devices are more like subscription endpoints than owned property.

Shifting to a repair‑friendly economy requires companies to rethink incentives—potentially moving toward longer‑term service relationships, certified third‑party networks, and circular‑economy business models instead of pure hardware churn.

The U.S. FTC notes that “there is scant evidence to support manufacturers’ justifications for repair restrictions,” while still recognizing the need to address genuine safety and security issues.

Practical Tools: How Users Can Support Right‑to‑Repair Today

While high‑level policy battles continue, individual users can already make meaningful choices that support repairability and reduce e‑waste.

Choose Repair‑Friendly Devices

- Consult iFixit repairability scores before purchasing smartphones, laptops, or tablets.

- Consider modular and repair‑focused brands such as Framework or Fairphone whenever they meet your needs.

- Look for devices with user‑replaceable batteries and standard connectors.

Equip Yourself for Basic Repairs

Many common issues—battery wear, sticky keys, clogged fans—are repairable with modest skills and the right tools. Some widely recommended starter tools include:

- A comprehensive but compact electronics toolkit such as the iFixit Pro Tech Toolkit , which includes precision bits, spudgers, and ESD‑safe tools.

- A reliable anti‑static wrist strap like the Rosewill RTK‑002 Anti‑Static Wrist Strap to protect components from electrostatic discharge.

- Quality replacement batteries from reputable vendors when the original manufacturer’s options are unavailable or impractical.

Learn from Trusted Guides and Communities

Before you open any device, check:

- iFixit’s step‑by‑step guides for your specific model.

- Video walkthroughs from established repair channels on YouTube.

- Forum discussions (e.g., on Reddit or manufacturer‑specific boards) about common pitfalls and safe practices.

Always back up your data, understand warranty implications, and evaluate whether a repair is within your skill level or better left to professionals.

The Future of Hardware: How Right‑to‑Repair Will Shape Design

As more jurisdictions mandate repairability and consumers prioritize longevity, hardware design is likely to evolve in several predictable directions.

Design Shifts on the Horizon

- Standardized parts for common components such as batteries and chargers, building on USB‑C standardization trends.

- Modular sub‑systems—for example, daughterboards for ports and wireless chips, making frequent failure points easier to replace.

- Accessible documentation, potentially delivered through secure online portals that still meet regulatory requirements for openness.

- Longer software support windows aligned with expected hardware lifetimes, preventing artificial obsolescence.

Repair‑Centric Business Models

Companies may also move toward:

- Certified independent repair networks with access to genuine parts and training.

- Subscription or extended support plans that emphasize keeping devices running rather than replacing them.

- Take‑back and refurbish programs that keep devices in circulation longer while recovering materials efficiently at end of life.

Conclusion: From Sealed Boxes to Shared Stewardship

The backlash against sealed gadgets is about more than fixing broken screens. It is a referendum on what ownership means in an era of cloud‑connected, software‑dependent devices. Legislative momentum in the U.S. and EU, corporate experiments with self‑service repair, and the growing influence of repair‑friendly pioneers like Framework and Fairphone all point toward a future where repairability is a standard design parameter, not an afterthought.

Achieving that future will require careful balancing of safety, security, intellectual property, and user autonomy. But the trajectory is clear: as the right‑to‑repair movement matures, it is reshaping expectations for how long devices should last, how transparent manufacturers should be, and how much control end users should wield over the tools they rely on every day.

For consumers, the most powerful steps are surprisingly straightforward: buy repairable devices, support companies that embrace openness, learn basic maintenance skills, and lend your voice—through votes, purchases, and social media—to policies and products that respect your right to fix what you own.

Additional Resources and Further Reading

To dive deeper into the technical, legal, and environmental aspects of right‑to‑repair, explore the following resources:

- iFixit – Right to Repair Overview

- The Repair Association (Repair.org)

- U.S. PIRG – Right to Repair Campaign

- European Parliament – Right to Repair Initiative

- U.S. Federal Trade Commission – Repair Restrictions Reports

- Louis Rossmann’s YouTube Channel – Deep dives into repair practice and policy.

Keeping up with ongoing coverage from Ars Technica, The Verge, and similar outlets will help you stay informed as new laws, devices, and industry practices continue to evolve.

References / Sources

- iFixit – Right to Repair News

- The Repair Association – Legislative Efforts

- Wired – Right to Repair, Explained

- The Verge – Right to Repair Coverage

- Engadget – Right to Repair Articles

- U.S. FTC – Nixing the Fix Report

- European Commission – E‑waste Policy

- OECD – Waste Electrical and Electronic Equipment