Why the Right to Repair Will Decide the Future of Your Gadgets

The battle over device longevity is no longer a niche fight between tinkerers and manufacturers. In 2024–2025, right to repair has become a central technology, environmental, and consumer-rights issue. From US statehouses and the European Parliament to YouTube teardown benches, a new social contract around gadgets is being negotiated: when you buy a device, do you truly own it—parts, software, and all—or are you merely licensing a sealed black box?

At stake are billions of dollars in hardware sales, the pace of electronic waste (e‑waste), and the practical lifespan of everything from smartphones and laptops to tractors and medical devices. As new rules roll out and major brands shift their policies, consumers, repair technicians, and policymakers are all asking the same question: how repairable should modern technology be?

Mission Overview: What Is the Right to Repair?

The right to repair is a policy and design movement that seeks to ensure consumers and independent technicians can fix devices safely and affordably. It typically demands that manufacturers:

- Provide access to genuine spare parts at fair prices.

- Offer service manuals, schematics, and diagnostic software.

- Stop using software locks or serialization to block legitimate repairs.

- Design products with reasonable disassembly and reassembly in mind.

Organizations like iFixit’s Right to Repair campaign and the U.S. PIRG Right to Repair initiative have pushed this agenda for over a decade. What is different today is momentum: lawmakers are increasingly writing repairability into law, while consumers see repair scores alongside camera specs and battery size in product coverage.

Legislative Momentum: From Niche Bills to Global Standards

In the last few years, right-to-repair proposals have turned into enacted laws across multiple regions. While the exact provisions differ, the shared goal is to extend device lifespans and rebalance power between manufacturers and users.

United States: State-by-State Progress

Several US states—including New York, Minnesota, and Colorado—have passed broad right-to-repair or “Digital Fair Repair” laws targeting consumer electronics. These typically require:

- Manufacturers to sell spare parts, tools, and diagnostic software to independent repair shops and end users.

- Publication of repair documentation comparable to what is provided to authorized service networks.

- Non-discriminatory pricing for parts and tools.

Other states including California and Massachusetts have debated similar measures, often shaped by intense lobbying from technology and medical device industries. Coverage in outlets like Ars Technica and Wired highlights how carve-outs for categories like gaming consoles, agricultural equipment, or security-sensitive components can limit the impact of these laws.

“Restricting independent repair can raise costs for consumers, stifle innovation, and generate unnecessary waste.”

European Union: Repairability as Policy Infrastructure

The EU has moved aggressively, weaving repairability into its broader Green Deal and circular economy initiatives. Key measures include:

- Ecodesign rules that require certain appliances and electronics to be built for easier disassembly and spare-part availability.

- Repairability scoring systems (such as France’s repairability index) that rate how easy it is to fix a product, influencing consumer decisions at the point of sale.

- Proposals for user-replaceable batteries in smartphones and other devices to reduce early obsolescence.

EU regulations often become de facto global standards because manufacturers redesign hardware and documentation for the largest markets. This means a European rule on spare parts or battery access can shape the smartphone you buy in the US or Asia—even without local legislation.

Global Picture

Countries such as Australia, Canada, and the UK are exploring similar paths. The OECD and environmental NGOs have increasingly cited right to repair as a lever to meet e‑waste and climate targets.

Technology and Manufacturer Responses: From Locked Black Boxes to Self-Service Repair

Facing regulatory pressure and shifting public sentiment, major hardware makers have launched a variety of repair programs. But the details reveal a complex mix of genuine progress and strategic limitation.

Apple, Samsung, Google, and Microsoft: Converging on Self-Service

Over the past few years, Apple, Samsung, Google, and Microsoft have all announced self-service or independent repair initiatives. Typical features include:

- Online portals to purchase original parts and specialized tools.

- Downloadable repair guides for specific models.

- Part pairing or calibration processes that must be completed during or after repair.

Tech outlets such as The Verge and Engadget frequently analyze these programs’ pricing and practicality. Critics on Repair-Tok (repair-centric TikTok channels) and forums like Hacker News argue that high parts costs, deposit-heavy tool rentals, and serialized components can still make professional third‑party repair or device replacement more appealing than DIY fixes.

“It’s a step forward when companies sell genuine parts, but if a screen swap still needs a proprietary software handshake, that’s control by another name.”

Serialization and Software Locks

One of the central technical battlegrounds is serialization—the practice of cryptographically pairing components like screens, batteries, and cameras to a specific device’s motherboard. When a serialized part is replaced, software may:

- Display warnings or disable certain features unless an authorized calibration tool is used.

- Refuse to accept non-genuine parts entirely.

- Limit functionality (for example, disabling biometric sensors).

Manufacturers justify serialization as a way to protect security and safety. Repair advocates counter that it often serves mainly to protect revenue and control over the repair ecosystem. Ongoing policy debates attempt to draw a line between legitimate security constraints and anticompetitive design.

Authorized Networks vs. Independent Shops

Business coverage in outlets like TechCrunch and Recode-style columns highlight a key economic question: will OEMs open their authorized repair networks to more independent shops, or will they continue to channel repairs through tightly controlled partners?

If the cost of joining an authorized program is high, or if terms remain restrictive, many local repair businesses could still be squeezed out—even if parts and manuals are technically available on paper.

Scientific and Environmental Significance: Device Longevity as Climate Policy

Right to repair is not only a consumer-rights issue; it directly intersects with environmental science, lifecycle assessment (LCA), and circular-economy policy.

Why Device Longevity Matters for the Planet

The majority of a smartphone’s lifetime carbon footprint is embedded in its manufacturing phase: mining and processing raw materials, semiconductor fabrication, assembly, and global shipping. Studies from the European Environment Agency and academic life-cycle analyses show that:

- Extending a smartphone’s life from 3 to 5 years can significantly reduce its annualized carbon impact.

- Reusing or refurbishing laptops and desktops often beats recycling because recycling cannot recover all the energy invested in the original production.

- Designing for easy part replacement vastly improves the economics of refurbishment.

Publications like Wired and TechRadar increasingly tie these findings into mainstream coverage, framing repairability not just as a nerdy preference but as a climate tool.

E‑Waste and Resource Constraints

The UN’s Global E-waste Monitor highlights that the world generates tens of millions of tons of e‑waste annually, much of it improperly handled. Precious and rare-earth metals are lost, while toxic components can contaminate soil and water.

By enabling repair and remanufacturing:

- Fewer devices are discarded early for minor failures (e.g., cracked screens, aging batteries).

- Components can be harvested and reused, reducing demand for virgin materials.

- Local repair economies can create green jobs with relatively low capital requirements.

“The most sustainable device is the one you already own—especially if you can repair it.”

Security and Safety Considerations

Security experts raise genuine concerns: open repair ecosystems could be abused to insert compromised components or tampered firmware. For example:

- Malicious replacement parts with hidden hardware implants.

- Refurbished devices that are resold with pre‑installed malware.

- Unvetted batteries or power supplies that increase fire risk.

Modern right-to-repair policy must therefore balance openness with verification. Secure boot chains, signed firmware, and hardware attestation can preserve security while still allowing third‑party physical repair—provided verification tools and documentation are accessible.

Culture and Community: Teardowns, Repair Scores, and the New Gadget Narrative

The cultural side of right to repair is driven by creators and communities who turn repair into content, education, and advocacy.

Teardown Channels and Repairability Scores

YouTube channels and TikTok accounts that systematically disassemble new phones, laptops, and game consoles are now part of a device’s launch cycle. iFixit’s well-known repairability scores and detailed guides often appear in coverage by The Verge, Ars Technica, and other outlets.

A low repairability score can affect the narrative of a flagship product, especially among power users and professionals. Conversely, devices designed with modular components and easily accessible batteries can earn praise that influences purchasing decisions.

Communities of Practice

Repair culture thrives in:

- Online forums such as Reddit’s /r/righttorepair and /r/hardware.

- Local repair cafés where volunteers help neighbors fix appliances and gadgets.

- Maker spaces that host electronics repair workshops alongside 3D printing and robotics.

These communities reduce anxiety about opening devices and create social norms that favor repair over replacement, especially when paired with policy that makes parts and guides available.

Visualizing the Battle Over Device Longevity

Milestones in the Right-to-Repair Movement

The journey from fringe activism to mainstream policy has been marked by several milestones often highlighted in technology and business media.

Key Turning Points

- Farm equipment and tractors became early flashpoints, as locked-down diagnostics pushed farmers toward advocacy.

- iFixit and other teardown sites normalized opening up devices and scoring their repairability.

- Major US state laws demonstrated that broad, electronics-focused repair legislation was politically feasible.

- EU ecodesign and battery rules moved repairability from consumer advocacy into environmental compliance.

Shifts in Corporate Messaging

As coverage on sites like The Verge, Wired, and Ars Technica intensified, manufacturers began to highlight:

- Longer software support windows for major product lines.

- Carbon-neutral and circular-economy commitments that include repair and refurbishment.

- Partnerships with recognized repair organizations or third‑party logistics for spare parts.

These public commitments create accountability: when teardowns reveal that a device is glued together in ways that contradict a brand’s sustainability messaging, critics have concrete evidence to point to.

Challenges: Security, Safety, Economics, and Design Constraints

The right-to-repair story is not a simple arc from “bad” sealed devices to “good” open ones. There are real trade-offs and unresolved tensions.

Security and Counterfeit Risks

Open repair ecosystems must manage:

- Counterfeit parts that may be unreliable or unsafe.

- Supply-chain vulnerabilities where compromised components are introduced.

- Data privacy concerns when unvetted shops handle devices containing sensitive information.

Solutions include traceable part provenance, secure diagnostics that do not expose private user data, and clear standards for independent repairer certification.

Ultra-Thin Design vs. Repairability

Consumers simultaneously demand thinner, lighter, and more powerful devices and better repairability. These goals can conflict:

- Water and dust resistance often rely on adhesives and sealed enclosures.

- High power density can push designs toward tightly integrated, non-modular components.

- Compact form factors reduce the physical space available for connectors and mounting hardware.

Thoughtful engineering can still balance these demands—for example, by using gasketed screws instead of glue, modular daughterboards, and accessible battery pull tabs—but it requires design priorities that explicitly value repair from the outset.

Economic Models and OEM Incentives

Historically, manufacturers have relied on frequent hardware upgrade cycles. Extending device lifespans forces a rethinking of:

- Revenue models (e.g., more services and software, fewer forced hardware refreshes).

- Warranty design, including whether third‑party repairs void coverage.

- Parts pricing strategies, which can either enable or discourage repair.

Business reporting in TechCrunch-style outlets often frames this as a battle between short-term margins and long-term brand trust and regulatory compliance.

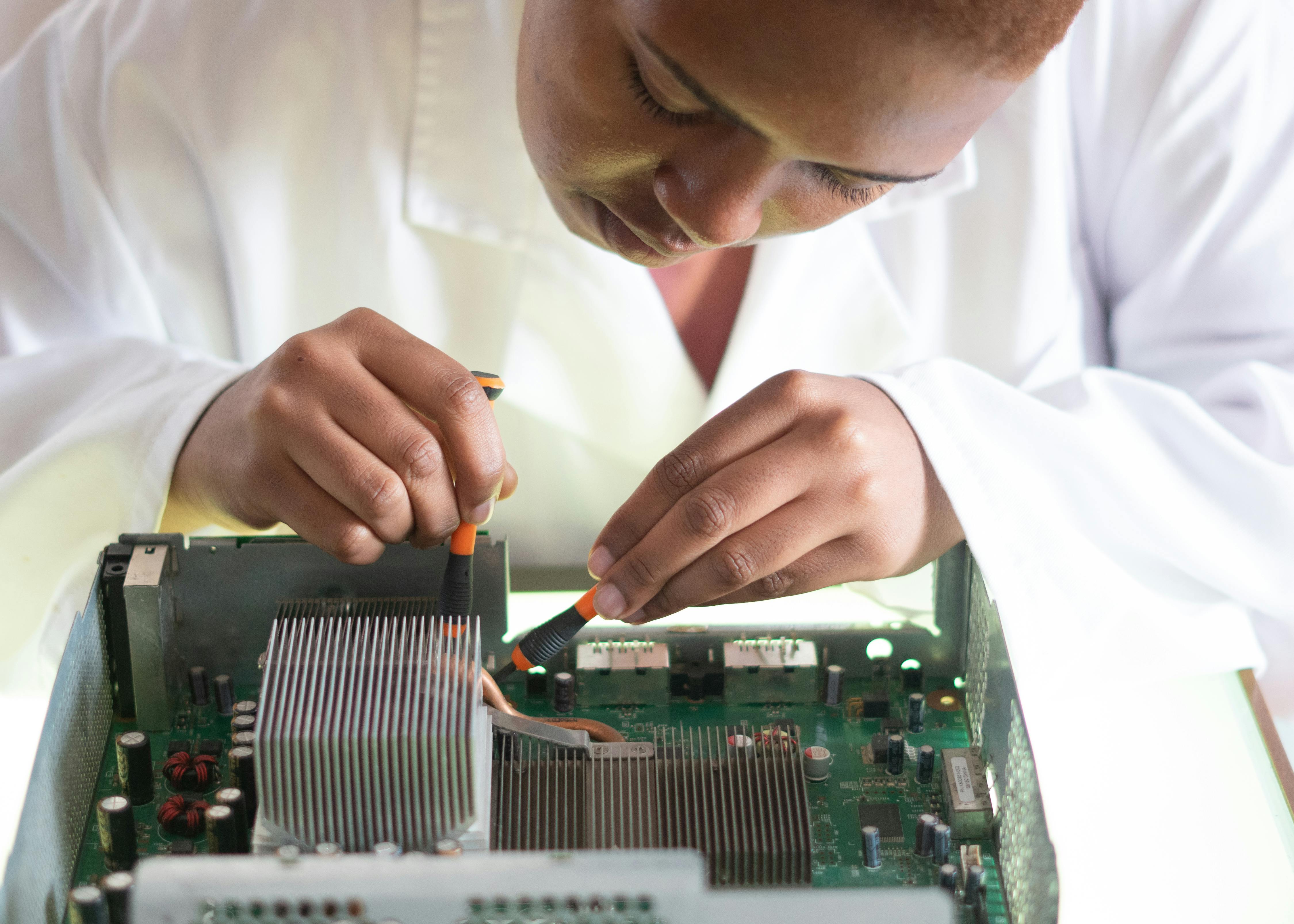

Practical Technology: How Repairs Are Actually Done

On the workbench, right to repair translates into tools, skills, and safe workflows. Modern electronics repair blends classic soldering with advanced diagnostics and micro-soldering techniques.

Essential Tools for Modern Device Repair

A capable repair setup typically includes:

- Precision screwdriver kits with interchangeable bits.

- Plastic prying tools and spudgers to avoid board and flex damage.

- ESD-safe tweezers, mats, and wrist straps.

- Magnification tools, such as a microscope or high-quality loupe.

- Hot air rework stations and fine-tipped soldering irons for board-level work.

For readers looking to experiment with safe, entry-level repairs and upgrades, products like the iFixit Mako Precision Bit Set are widely recommended in the US repair community thanks to their high-quality bits and compatibility with common electronics fasteners.

“Good tools don’t just make repairs easier—they make them safer for both you and the device.”

Methodology: Safe Repair Workflows

A typical smartphone repair workflow might involve:

- Documenting the device condition and backing up data when possible.

- Powering down, disconnecting the battery, and working on an ESD-safe surface.

- Following a step-by-step guide from a trusted source (e.g., iFixit or manufacturer documentation).

- Organizing screws and components methodically to avoid confusion during reassembly.

- Testing all critical functions (display, touch, cameras, radios, sensors) before sealing the device.

Professional repair shops add intake forms, customer consent, and diagnostic reports to this process for accountability and safety.

What Consumers Can Do Today

Even before every jurisdiction adopts strong right-to-repair laws, consumers can influence device longevity trends with their own decisions.

Before You Buy

- Check repairability scores and teardown reports from sources like iFixit and major tech sites.

- Look for clear statements on software support windows and spare-part availability.

- Prefer products with user-accessible batteries where possible.

While You Own the Device

- Use protective cases and screen protectors to avoid common damage modes.

- Keep software updated for security, but avoid unnecessary hardware upgrades.

- Repair or refurbish older devices before recycling them—and consider donating working hardware.

Engage in Policy and Community

- Support local repair businesses and repair cafés.

- Follow advocacy groups and stay informed about pending legislation in your region.

- Share your positive repair experiences; social proof influences both friends and manufacturers.

Conclusion: From Disposable Gadgets to Durable Companions

The right-to-repair movement reframes our relationship with technology. Instead of rapid replacement cycles and opaque hardware, it pushes toward devices that we can understand, maintain, and upgrade. This shift supports:

- Consumers, by lowering lifetime costs and restoring control over owned hardware.

- The environment, by extending product lifespans and reducing e‑waste.

- Innovation, by enabling independent experimentation, modification, and small-business repair ecosystems.

The battle is not over. Manufacturers, regulators, security experts, and repair advocates will continue to negotiate the boundaries between openness and safety, user freedom and ecosystem integrity. But the direction of travel is clear: device longevity and repairability are now core parts of how we evaluate and govern technology.

As laws mature and repair programs improve, future hardware could become less of a sealed, disposable appliance and more of a durable, serviceable companion—something we carry for many years, not just until the next product announcement.

Additional Resources and Further Reading

To explore this topic more deeply, consider these resources:

- iFixit – Right to Repair Hub for guides, scores, and advocacy updates.

- U.S. PIRG – Right to Repair for US policy developments and consumer action toolkits.

- Louis Rossmann’s YouTube Channel for in-depth board-level repair demonstrations and policy commentary.

- Right to Repair Europe for EU-focused campaigns and regulatory analysis.

- Popular explainer video on the right to repair for a concise, visual overview suitable for sharing.

Tracking how major outlets like Ars Technica, Wired, The Verge, and TechRadar cover each new device launch—with an eye to repairability, parts availability, and support timelines—can give you an informed edge when choosing your next gadget.

References / Sources

- European Commission – Circular Economy and Ecodesign: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en

- US PIRG – Right to Repair: https://uspirg.org/topics/right-repair

- iFixit – Right to Repair Campaign: https://www.ifixit.com/Right-to-Repair

- UN Global E-waste Monitor (ITU/UNITAR): https://www.itu.int/en/ITU-D/Environment/Pages/Spotlight/Ewaste/Ewaste.aspx

- Right to Repair Europe: https://repair.eu

- FTC – Nixing the Fix Report on Repair Restrictions: https://www.ftc.gov/reports/nixing-fix-ftc-report-repair-restrictions