Why Right-to-Repair Is Reshaping Consumer Tech in 2025

For more than a decade, consumer electronics quietly became harder to fix: glued-in batteries, proprietary screws, encrypted diagnostics, and software locks turned once-repairable devices into sealed black boxes. By 2025, that trend has collided with public frustration, climate imperatives, and increasingly assertive regulators, transforming the right-to-repair and anti-obsolescence push into a central storyline of modern consumer tech.

At its core, the right-to-repair movement insists that if you buy a device, you should be able to maintain, modify, and repair it—either yourself or at an independent shop—without facing artificial technical or legal barriers. The anti-obsolescence push goes a step further, demanding that devices be designed for longevity, upgradability, and efficient reuse rather than premature replacement.

“If you can’t fix it, you don’t really own it.”

Media outlets like The Verge, Wired, and Ars Technica now track every major legislative development, corporate policy shift, and teardown controversy. Meanwhile, YouTube and TikTok creators—especially teardown and repair specialists—have turned repairability into viral, visual storytelling that reaches millions of viewers.

Mission Overview

Right-to-repair and anti-obsolescence advocates share a broad mission: realign consumer tech with user ownership, longevity, and sustainability. That mission can be distilled into three intertwined goals:

- Restore functional ownership: When you buy hardware, you should control how, where, and by whom it is repaired.

- Extend device lifespans: Through better design, accessible parts, and ongoing software support, devices should remain useful for far longer than typical upgrade cycles.

- Reduce environmental impact: Longer-lasting products mean less e-waste, lower resource extraction, and smaller carbon footprints.

Historically, manufacturers have often pursued thinness, integration, and ecosystem lock-in at the expense of repairability. Batteries were glued rather than screwed in; RAM and storage were soldered to the board; display panels were fused to glass; and cloud-linked activation locks tied physical parts to online accounts and proprietary servers.

By 2025, the counter-movement has compelled lawmakers, regulators, and many major brands to formally recognize repairability and longevity as design requirements rather than optional “nice-to-haves.”

Technology

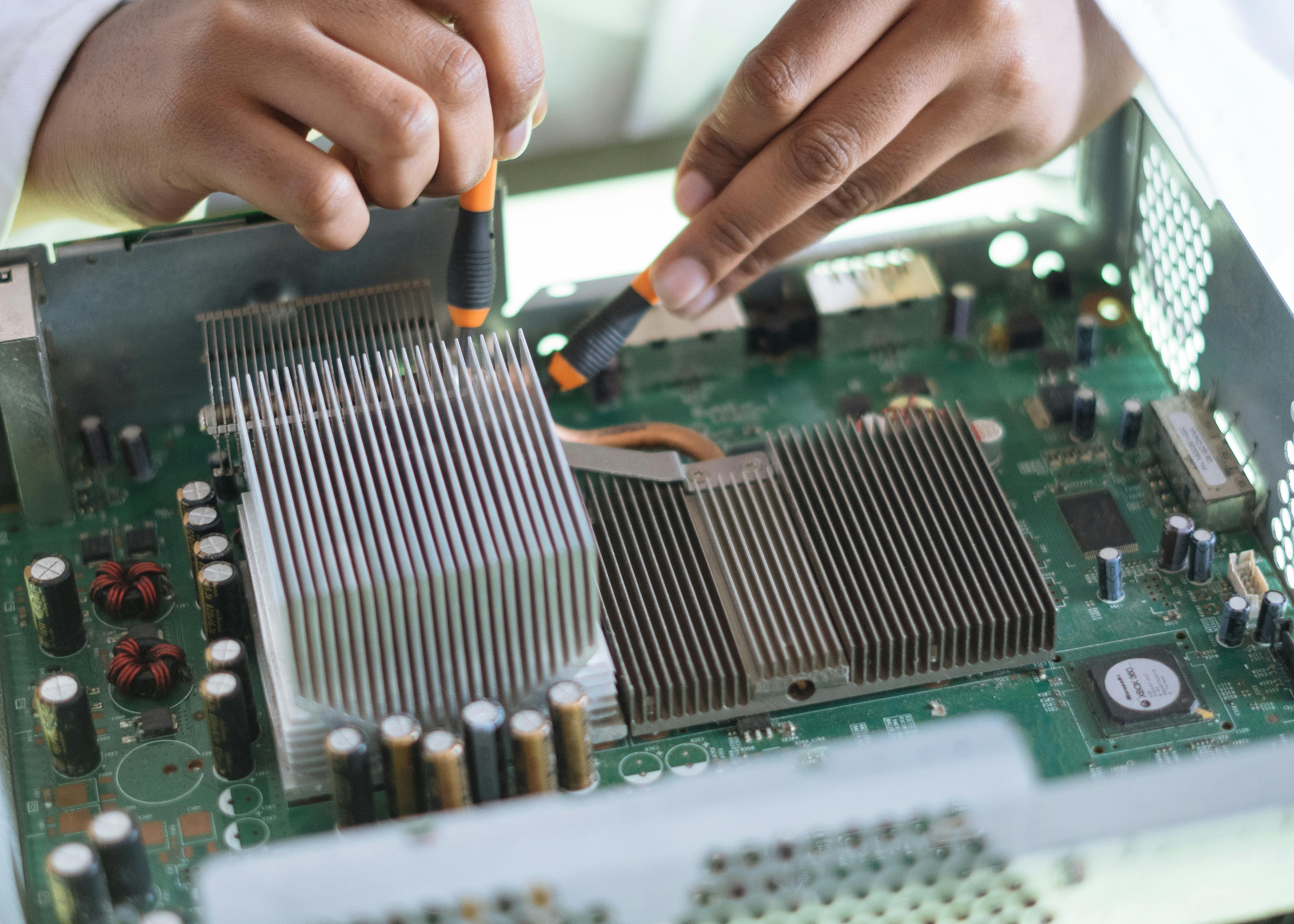

The technical battleground of right-to-repair is found in product design decisions, firmware architectures, and software ecosystems. These are some of the key technologies and design practices shaping the repair debate.

1. Hardware Design: From Glue and Solder to Screws and Modules

One of the most visible trends has been the shift from integrated, glued designs to more modular, screw-based assemblies in certain product lines. Devices like the Framework Laptop and some EU-focused models of mainstream phones showcase:

- User-replaceable batteries with pull tabs and standard screws

- Separate, swappable USB-C ports and daughterboards

- Keyboard and trackpad assemblies that can be changed without destroying the top case

- Standardized M.2 SSDs and accessible RAM slots

Meanwhile, many flagship smartphones still rely on copious adhesive and fused displays, making key repairs expensive or risky, even when parts are available.

2. Parts Pairing and Cryptographic Locks

A major flashpoint is parts pairing, where components (like screens, batteries, or cameras) are cryptographically tied to a device’s logic board via unique identifiers. Without an authorized calibration or software “blessing,” replacement parts may:

- Trigger warning messages about “non-genuine” components

- Disable advanced features (e.g., True Tone displays, biometric sensors)

- Refuse to function entirely

“When software is used to artificially limit hardware functionality after a repair, it stops being about safety and starts being about control.”

3. Diagnostic Tools and Firmware Access

Access to diagnostic modes, service menus, and firmware-level calibration tools is essential for modern repairs. Historically, these tools have been restricted to authorized service centers under NDAs.

In response to legislation—especially in the EU and some US states—several manufacturers have introduced:

- Self-service repair portals with downloadable manuals and official parts

- Public diagnostic applications that run on consumer devices

- Cloud-based calibration tools, accessible to independent shops for a fee

Critics note that high prices, geographic restrictions, and remaining software locks often blunt the impact of these programs.

4. Software Support and Update Policies

A device’s usable life is now dictated as much by software support as by hardware durability. Extended OS and security updates are increasingly intertwined with anti-obsolescence efforts:

- Regulators in the EU have pushed for mandatory multi-year update commitments for phones and tablets.

- Some Android vendors now advertise 5–7 years of security updates, aligning with premium device prices.

- Firmware updates can either enable broader parts compatibility—or tighten locks on unofficial repairs.

A key question in 2025 is whether mandated support windows will become a global norm, effectively setting a floor for device longevity.

Scientific Significance

Right-to-repair is not just a consumer rights story; it is deeply entangled with environmental science, materials engineering, and lifecycle assessment.

E-Waste and Lifecycle Analysis

The United Nations estimates that the world generates tens of millions of metric tons of electronic waste annually, much of it improperly recycled or dumped. Each smartphone or laptop embodies:

- Rare earth elements and critical minerals (e.g., cobalt, neodymium, lithium)

- Energy-intensive semiconductor manufacturing

- Complex supply chains spanning multiple continents

Lifecycle analyses consistently show that the bulk of a device’s total environmental impact occurs before you even turn it on, during raw material extraction and manufacturing. Extending device lifetimes through repair and refurbishment can therefore dramatically reduce per-year emissions and resource use.

Design for Disassembly and Circular Economy

Engineers focused on circular economy design emphasize:

- Design for disassembly – components that can be safely and quickly separated for repair or recycling.

- Material identification and labeling – plastics and composites that are clearly marked to guide recyclers.

- Modular upgrade paths – swapping a module (e.g., a camera or wireless card) instead of an entire device.

These principles feed into standards work at organizations like the ISO and inform policy efforts in the EU’s Ecodesign framework.

Data, Security, and Reliability Research

Opponents of broad right-to-repair rules often invoke safety and security risks, arguing that unauthorized modifications could compromise device integrity or user data. This has spurred research into:

- Secure but open diagnostic protocols

- Component attestation mechanisms that distinguish between malicious tampering and legitimate repairs

- Verification methods for refurbished parts that maintain safety standards

The scientific challenge is to design systems that are simultaneously robust, secure, and repairable.

Milestones

Between 2020 and late 2025, a series of legislative, corporate, and cultural milestones has elevated right-to-repair from a fringe concern to a mainstream policy agenda.

1. Legislative Wins and Regulatory Frameworks

Various jurisdictions have introduced or strengthened repair-friendly rules, often focusing first on smartphones, laptops, and household appliances. While details differ, common elements include:

- Requirements for manufacturers to publish repair manuals and schematic diagrams.

- Obligations to supply spare parts and tools for a defined period after sale (often 5–10 years).

- Limits on using software to block third-party repairs without a demonstrable safety justification.

The European Union has pushed especially hard via its Right to Repair initiatives and ecodesign regulations, influencing global design practices for devices sold in its large market.

2. Corporate Policy Shifts: Self-Service Repair and Longevity Messaging

Under mounting pressure, many major tech firms have:

- Launched self-service repair programs for phones, laptops, and desktops.

- Extended software support windows and publicly advertised their duration.

- Released repairability scores for certain models in markets where disclosure is required.

Tech journalists regularly compare these programs against independent standards, highlighting:

- Whether parts are priced reasonably versus full device replacement.

- Geographic coverage outside North America and Europe.

- Any ongoing reliance on parts pairing that undercuts practical repair.

3. Cultural Milestones: Viral Teardowns and DIY Influencers

Platforms like YouTube and TikTok have turned teardowns into a form of investigative journalism. Channels such as repair shops and teardown creators, and organizations like iFixit, produce content that:

- Assigns repairability scores to phones and laptops.

- Documents hidden design choices, like unnecessary glue or fragile cables.

- Shows audiences how to perform basic repairs safely.

Viral videos exposing devices that are nearly impossible to fix have repeatedly triggered broader coverage in outlets like The Verge and The Next Web, feeding into consumer sentiment and policy debates.

Challenges

Even with growing momentum, significant technical, economic, and legal obstacles remain.

1. Balancing Thinness, Performance, and Repairability

Product designers must juggle:

- Form factor: Consumers expect slim, lightweight devices.

- Performance and thermals: High-performance chips need robust, often tightly integrated cooling.

- Structural integrity: Screwed or modular designs can introduce flex points or additional seams.

Some Hacker News discussions argue that full modularity could constrain innovation in areas like high-density batteries or advanced camera stacks. The consensus among many engineers is that the target is not perfectly modular devices everywhere, but smart modularity where it matters most (batteries, storage, ports, common failure points).

2. Security, Privacy, and Counterfeit Parts

Manufacturers warn that poorly executed repairs or counterfeit parts can:

- Compromise device safety (e.g., battery fires, poor insulation).

- Expose users to data theft (e.g., malicious replacement components).

- Degrade brand reputation when “fixed” devices fail.

Researchers are exploring frameworks where:

- Independent repair shops can register and authenticate via open standards rather than closed ecosystems.

- Genuine third-party components can be cryptographically verified without tying them to a single device.

- Security prompts clearly inform users about repair history without disabling functionality unnecessarily.

3. Economic Incentives and Business Models

Device makers have long relied on rapid upgrade cycles. Anti-obsolescence threatens to lengthen replacement intervals, forcing companies to rethink revenue models:

- Shifting from one-time sales to service and subscription revenue.

- Offering official refurbishment programs that compete with independent refurbishers.

- Designing products for second and third lives in different markets.

For consumers, this tension often shows up in pricing: are repair parts and tools genuinely affordable, or are they being priced to nudge people toward buying new devices?

4. Global Inequities

Many rights and programs discussed in tech media apply primarily to wealthier markets. In low- and middle-income countries, independent repair has been a necessity for years, but:

- Access to official parts and tools is limited.

- Grey markets for salvaged and cloned parts flourish, with mixed quality.

- Legal protections for repair shops can be weak or poorly enforced.

A key question for the late 2020s is whether global agreements or multinational standards can reduce these inequities and recognize the existing expertise of repair communities worldwide.

Practical Steps for Consumers

While policy debates continue, consumers can already make more repair-friendly, anti-obsolescence choices.

1. Evaluate Repairability Before You Buy

Before purchasing a new device, look for:

- Independent repairability scores (for example from iFixit).

- Official statements on software support duration.

- Availability of spare parts and manuals on manufacturer or partner sites.

2. Start with Safe, Basic Repairs

Many common issues—battery degradation, worn-out fans, clogged ports—are approachable with the right tools and guides. Quality, ESD-safe toolkits reduce the risk of damage. For instance, a well-reviewed precision toolkit like the iFixit Mako Precision Bit Set provides the specialty bits needed for most modern electronics.

3. Use High-Quality Replacement Parts

When replacing consumables, prioritize safety and reliability. For example, for laptops and desktops, high-quality SSDs with good endurance ratings can extend life significantly. Products such as the Samsung 870 EVO 1TB SSD are widely used for breathing new life into older systems.

4. Learn from Reputable Guides and Communities

Step-by-step visual guides from sources like iFixit, reputable YouTube channels, and specialized forums reduce repair risk. Always cross-check guides for your exact model, and read comments for up-to-date tips about hidden clips, fragile cables, or firmware quirks.

5. Support Pro-Repair Policy and Transparency

Public comments to regulators, petitions, and direct feedback to manufacturers all influence the pace of change. Following subject-matter experts on platforms like LinkedIn or X (Twitter) debates on right-to-repair can keep you informed and amplify well-founded analysis.

Beyond Phones and Laptops

By late 2025, right-to-repair pressure has expanded to a wide spectrum of products:

- Gaming consoles: Debates over user-friendly cleaning, fan replacement, and storage upgrades.

- Smart home devices: Concerns about cloud lock-in and what happens when servers are shut down.

- Electric scooters and bikes: Battery pack replacement, controller repair, and open diagnostics.

- Some EV components: The frontier of high-voltage battery serviceability, software locks, and third-party repair rights.

Each category raises domain-specific safety and regulatory issues, especially around batteries and high-voltage systems, but the underlying ownership question is the same: Do you own the hardware you paid for?

Conclusion

Right-to-repair and anti-obsolescence efforts have shifted the center of gravity in consumer tech. Design meetings that once focused almost exclusively on aesthetics and performance now must account for regulatory requirements, repairability scores, and sustainability targets.

The coming years will likely determine whether:

- Repairability becomes an industry-wide baseline, like USB-C or Wi‑Fi, or remains a niche selling point.

- Parts pairing and software locks are tamed by transparent standards or continue as opaque, proprietary controls.

- Consumers embrace longer ownership cycles with a culture of maintenance, refurbishing, and responsible resale.

Whatever the outcome, the narrative has already changed. Planned obsolescence is no longer a quiet default—it is a contested, visible choice. And in that contest, legislatures, engineers, independent repairers, and everyday users all have a role to play.

Further Learning and Resources

To dive deeper into the technical, policy, and environmental aspects of right-to-repair and device longevity, explore:

- iFixit’s Right-to-Repair hub – background, campaigns, and detailed teardowns.

- European Commission: Right to Repair – official EU initiatives and legislative texts.

- The Repair Association – advocacy, policy tracking, and position papers.

- Smartphone teardown playlists on YouTube – real-world demonstrations of repair challenges and successes.

- World Economic Forum: Circular economy articles – broader context on materials, design, and sustainability.

References / Sources

Selected references for further reading and verification:

- The Verge – Right-to-Repair coverage

- Wired – Right-to-Repair tag

- Ars Technica – Analysis of right-to-repair laws in the US and Europe

- United Nations – Global E‑waste Monitor

- European Commission – Right to Repair initiative

- iFixit – Teardowns, guides, and repairability scores

- The Repair Association – Policy and advocacy resources